3D printing company Renishaw and US engine manufacturing company have joined forces to improve the design process of aircraft and motorcycle engines.

Cobra Aero has invested in Renishaw’s AM 400 system to increase its additive manufacturing (AM) capabilities and collaborated with Renishaw engineers to use AM to improve the design of a cylinder for an unmanned aerial vehicle (UAV).

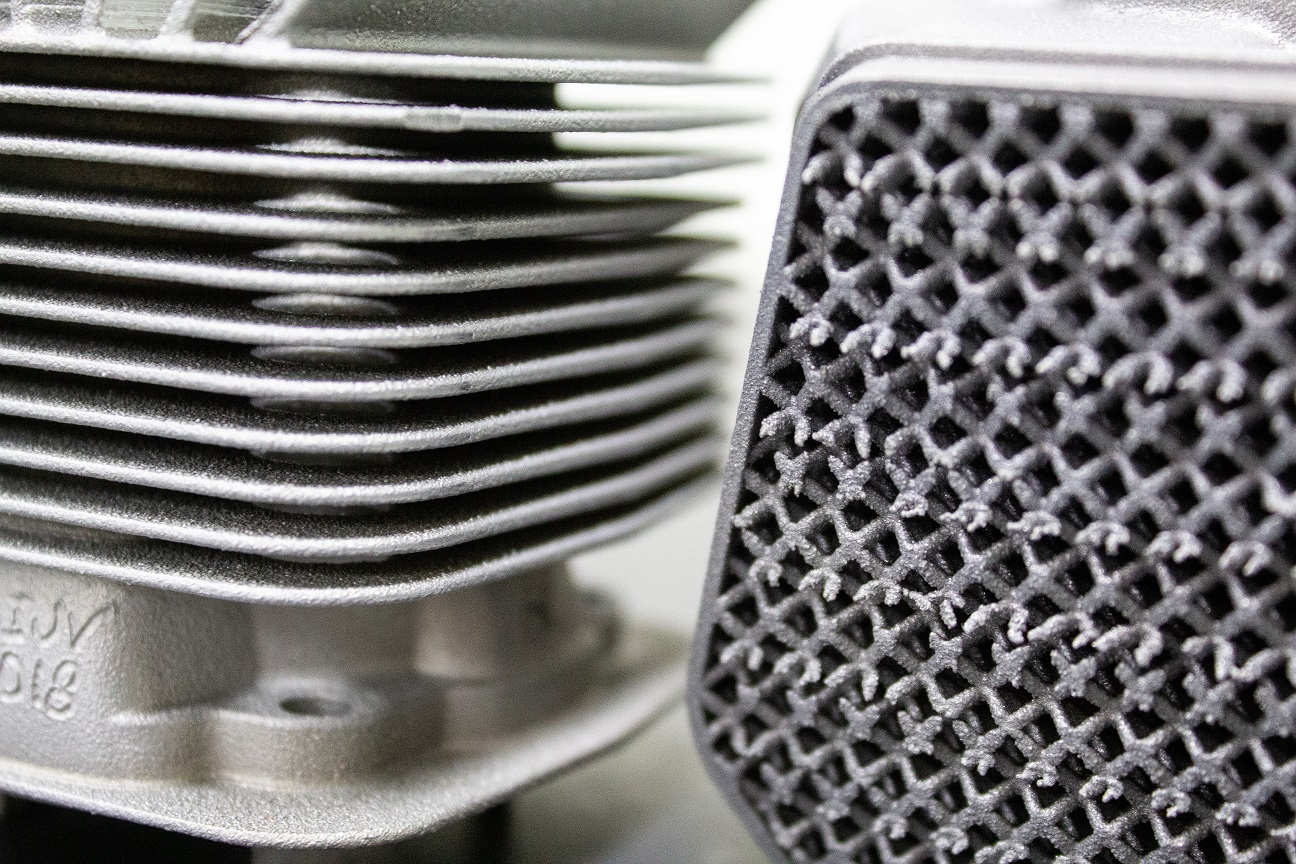

Using AM technology the company designed a lattice structure to increase airflow which could be produced in one solid, lightweight part.

‘We decided to redesign the cylinder because of its importance in an engine,’ said Sean Hilbert, president of Cobra Aero. ‘Design changes to this part of the engine must happen rapidly and it is also a high value part.’

This story uses material from the Renishaw, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.