The US Army Research Laboratory (ARL) has collaborated with the University of Central Florida (UCF) to 3D print lighter components for Army personnel.

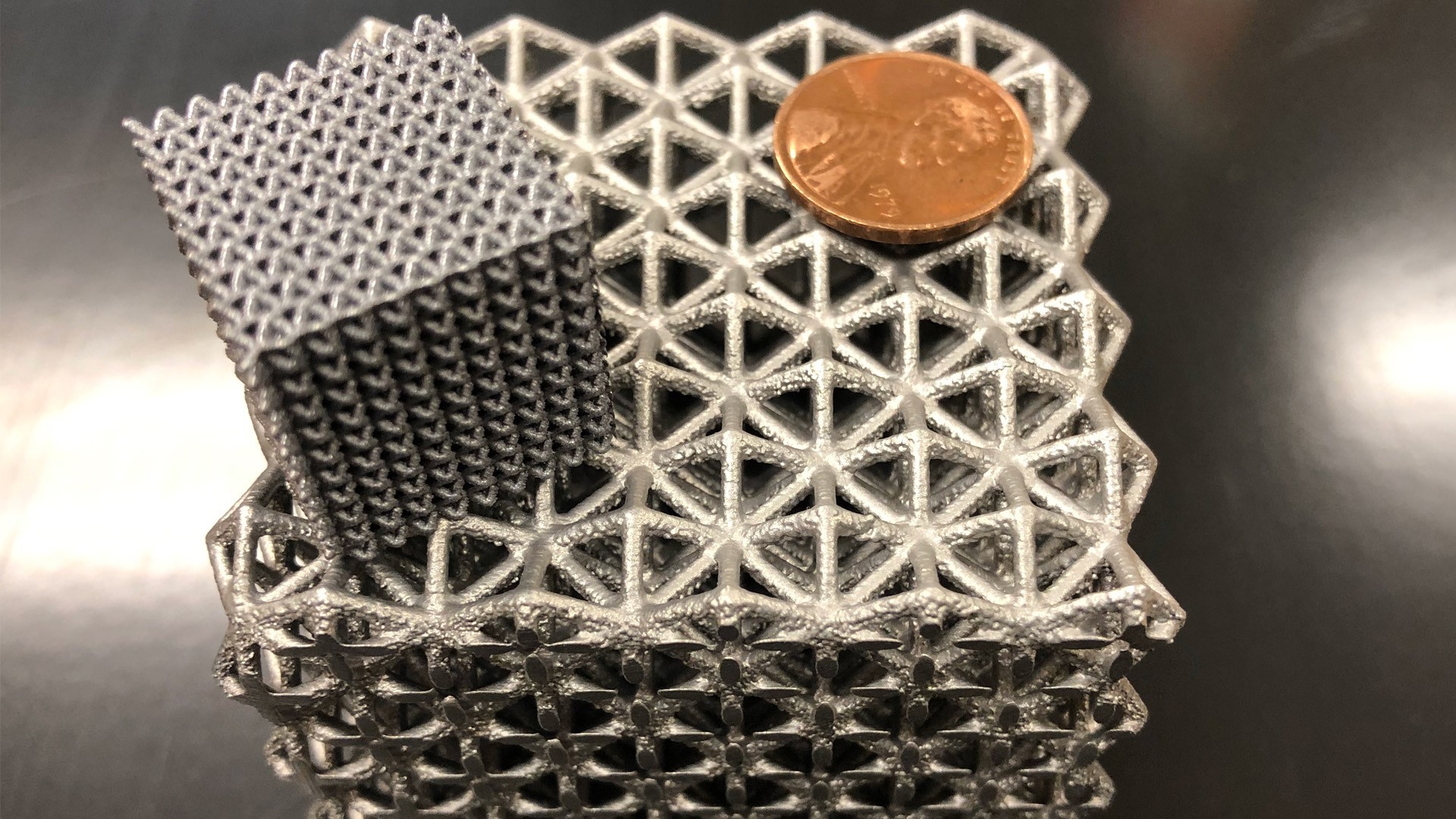

Plans are to improve the additive manufacturing (AM) of a high-strength magnesium alloy by increasing the density enough to make 24 micro-lattice structures.

‘We used a magnesium alloy known as WE43, which has only been successfully 3D printed by a handful of researchers,’ said Dr Brandon McWilliams, lead researcher at ARL. ‘In this work, we optimized the process to achieve higher density than previously reported and used that to produce and characterize lattice structures made up of WE43.’ Magnesium Elektron WE43 is a high strength casting alloy which can be used in temperatures of up to 300°C (572°F), according to the Lab.

‘Current [weapons] systems are too heavy, which increases burden to the soldier, reduces fuel efficiency and degrades mission effectiveness,’ said Dr McWilliams.

Army researchers will now evaluate the high strain rate and ballistic properties of these 3D-printed materials and look for demonstration applications, such as ultra-lightweight unmanned aircraft syste and robotic vehicle components, he added.

This story uses material from the ARL, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.