Steel and aluminum panels in assemblies often will undergo surface finishing for reasons ranging from cosmetics to performance, while stainless steel panels may require passivation. For any assembly subject to surface finishing and requiring self-clinching hardware, a central question will arise: How and when should a metal panel be surface finished without degrading the installed performance of the self-clinching fasteners? A basic understanding about self-clinching fastener technology and the issues associated with surface finishing can help guide the way toward best practices.

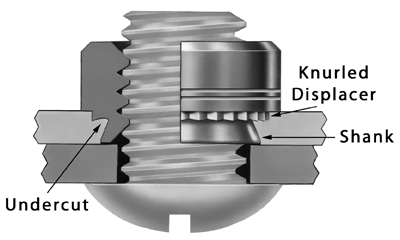

Self-clinching fasteners provide permanent and reusable load-bearing threads in thin metal sheets and historically have been specified in sheet metal too thin to allow for secure fastening by any other method. Upon installation (usually during the fabrication process), they become integral parts of an assembly, will not loosen or fall out (even when the mating thread is removed), and never have to be restrained from rotation with a tool. Clinching of these fasteners is enabled by a non-round displacer feature, which embeds into the host panel and displaces panel material into the fastener’s undercut. (See Figure 1.)

This results in the fastener’s permanent attachment in a panel with the capability to withstand rotation (because of the non-round displacer) and axial force (because of the displaced panel material in the undercut). Panels must always be sufficiently ductile to cold flow without fracturing, and fasteners must always be sufficiently harder than the panel to prevent fastener deformation, even as the panel is deformed during the installation process. Although it is always preferable to avoid surface finishing an assembly after self-clinching fasteners have been installed, sometimes this approach may be necessary.

Among the cosmetic reasons for applying a finish to an assembly after fastener installation, there may be concerns that a finished panel would be scratched or otherwise damaged when subsequently handled for fastener installation; there may be a desire to achieve the same color and texture both on the panel and the fasteners; and/or there may be a requirement to achieve surface properties on the fastener unavailable with the standard fastener finish. (Such surface properties may include low light reflectance, color fastness, and “non-stick” properties for clean room applications.)

Another typically encountered reason to apply a finish to an assembly after fastener installation is that some surface treatments on a panel may be detrimental to the self-clinching process when applied before fasteners are installed. These include hard-coat anodizing of aluminum panels and nitriding of steel panels. Such panel treatments increase the hardness and decrease the ductility of a panel’s surface—making the panel surface more resistant to the cold flow required during installation of a self-clinching fastener. Powder coating a panel, too, becomes an issue, because the typical thickness of .003"/ .076mm prevents full installation of the displacer feature on the fastener. Thin brittle platings (such as hardened electroless nickel) also will prove problematic, because they will crack and/or flake off from the severe deformation they must undergo during fastener installation. Thick hot dip galvanizing will likely exhibit some of the same hard panel and brittle plating issues.Hazards of Finishing with Fasteners InstalledMost surface finishing processes are “wet” and can pose several hazards when an assembly will be finished with self-clinching fasteners already installed.

The first hazard: Fastener damage from an incompatible finishing process. An extreme example is installing a steel fastener into an aluminum panel and then anodizing the assembly. The anodizing solution will almost totally destroy the steel fastener. Sometimes, the incompatibility will be less obvious. A frequently reported issue involves zinc plating a steel panel with steel fasteners installed. Since both are steel, a typical presumption is that a plating process appropriate for the panel will also be appropriate for the fastener. This may not be the case.

Steel panels usually are low carbon steel in a slightly work hardened condition—generically cold rolled steel. Because self-clinching fasteners must be harder than the panel in which they will be installed (typically by about 20 points on the HRB or HRC scale), most steel fasteners will be heat-treated. Steel fasteners produced by machining will exhibit high carbon on their surface due to the case hardening process and will have numerous inclusions on the surface from the free-machining ingredients. As a result, these fasteners may experience degradation during a pretreatment designed solely for cold rolled steel. They may also be susceptible to hydrogen embrittlement from exposure to atomic hydrogen during acid cleaning or electroplating. Another example of an incompatible process is a panel treatment such as nitriding, whose temperatures may be detrimental to fastener integrity.

A second hazard unique to wet processing: Trapped caustic solutions. The fastener-to-panel connection is all-metal and may not always be liquid tight. Although this joint may be liquid tight in the classic sense of preventing liquid from passing through, there are almost always crevices, particularly on the shank side of the fastener, which can trap processing solutions. A typical example is a self-clinching standoff. (Note the cavity beyond the fastener head as shown in Figure 2.)

When processing solutions become trapped, troubles follow. If the solution is caustic, the solution will continue to attack the surrounding metal, which can degrade the strength of the clinch connection and/or cause a cosmetic problem on the surface of the panel and/or the fastener. Even if effective rinsing renders any trapped solutions non-caustic, their entrapment under the finish can flash to steam—causing the plating to bubble if the assembly is subsequently heated above the boiling point of the trapped liquid.

A third hazard: Tight threads from excessive plating buildup in the threads. This plating buildup effect will cause “tight,” or non-gageable, threads. Most self-clinching fastener manufacturers produce threads in their steel parts with an appropriate allowance to accept the provided plating thickness as standard. Common plating thickness is a minimum of .0002" (5 microns), which allows for a maximum plating thickness of .0004" (10 microns). But this value should always be confirmed with the fastener manufacturer and never assumed.Even when the allowance is known, plating an assembly can still present pitfalls. If the fasteners were previously plated, the plating must be completely stripped from the threads for the original allowance to be available for the re-plating. It is also important to note that stainless steel and aluminum fasteners typically have no thread allowance for any type of additive plating or coating.

Guidance for Mitigating the HazardsWhen valid reasons exist to surface finish an assembly and none of the avoidance techniques is feasible, there are ways to plate an assembly successfully with self-clinching hardware already installed (See Table 1). While some issues may arise, the following guidelines can help optimize outcomes.Anodizing or Conversion Coating Aluminum Panel Assemblies. For non-heat treatable aluminum alloy panels, such as 5052, aluminum fasteners (which are always made from a heat treatable aluminum alloy) can be used. In these cases, the entire assembly can be anodized or given a conversion coating. Typically, there are no major issues with assemblies processed in this manner when rinsing is adequate to eliminate potentially trapped caustic solutions. When aluminum assemblies are clear anodized, the fasteners may have a slightly different appearance (usually darker) after anodizing, due to the alloying elements present in the fasteners. Common alloys for aluminum fasteners are 2024 in the T4 condition and 7075 in the T6 condition. Although marginal on strength for clinching, 6061-T6 is used for some aluminum fastener components not containing the clinch feature.

Panels made from heat-treatable aluminum alloys in the hardened condition are normally too hard for aluminum fasteners, which have a maximum panel hardness limit of HRB 50. As a result, 300 Series stainless steel fasteners are often specified. When this is the case, the assembly cannot be anodized, but a conversion coating can be applied. Experience has shown that the conversion coating process may need to be adjusted slightly to keep the stainless fasteners from darkening. The adjustment will involve making the acid etch step (prior to the actual chromate conversion step) less aggressive.

Electroplating Steel Panel Assemblies. The most common practice with steel panels is to use steel fasteners and the most common surface finish on steel panels is zinc electroplating. The lowest risk procedure will be to plate the panel first and then install plated fasteners. When this cannot be done, the second lowest risk procedure is to purchase unplated steel fasteners, install them, and then plate the assembly. This eliminates the need to strip the zinc plating from the fasteners, which could potentially damage the surface of the fastener.

When plated fasteners are used, extreme care must be taken in stripping the plating from them. Case hardened fasteners are particularly susceptible to acid damage during stripping, because of the high carbon content of their surface. A contributing factor is that many inhibitors used in acids are much less effective in preventing attack of high carbon steels than they are in preventing attack of low carbon steels, such as the typical cold rolled steel panel. Through- or neutral-hardened fasteners are only slightly more susceptible to acid attack than cold rolled steel and, generally, are not damaged by acid during stripping and re-plating an assembly.

All case hardened parts and high hardness through hardened parts are susceptible to hydrogen embrittlement and should be appropriately baked after plating, unless it can be established with certainty that a particular plating process is not embrittling to a particular fastener. Fasteners used in tension, such as a self-clinching stud in a critical application, should always be appropriately baked for hydrogen relief if the hardness is at or above the value at which the applicable plating standard requires baking. (The fastener manufacturer can be consulted for fastener hardness values to determine the need for baking and the appropriate baking process parameters.)

Although less common, 300 Series stainless steels are sometimes used in steel panels. Because the process needed to electroplate 300 Series stainless steel is so different from the process for plating a carbon steel panel, attempts to plate an assembly of a steel panel with 300 Series stainless steel fasteners are rarely—if ever—successful. (The most common problem is poor plating adhesion on the fasteners.)Passivating Stainless Steel Panel Assemblies. An important consideration in passivating stainless steel assemblies is choosing a passivation process appropriate both for the panel alloy and the fastener alloy.

The most common stainless steel panel alloy is Type 304, with Type 316 also used, but less frequently. Because of the required differential hardness required, self-clinching fasteners used in Type 304 or 316 panels will not be 300 Series. When corrosion resistance is not a controlling requirement, fasteners from Type 410 or Type 416 stainless steel offer a cost-effective solution. When greater corrosion resistance is required, a precipitation hardening grade such as 17-4 (UNS S17400) or A286 (UNS S66286) will be used for the fastener. Regardless, if an assembly must be passivated, the fastener manufacturer should be consulted for the exact alloy of the fastener for proper guidance relative to industry standards.Paint or Powder Coating Assemblies (Any Material). With the possible exception of very thin paint, paint or powder coatings are too thick for the standard thread allowance of self-clinching fasteners. Therefore, threads should be masked prior to painting or powder coating an assembly. In some cases fasteners can be ordered with mask pre-applied from the manufacturer. Other options include plugs and caps specifically designed for this purpose to mask internal and external threads, respectively. However, masking with caps and plugs can create multiple crevices for entrapping solutions if they are applied before any wet process pre-treatment step. Ideally, they should be applied after any wet processing. (A heavy layer of grease applied to the threads can also serve as an effective mask, but the grease must be able to survive the pretreatment or be applied after pretreatment.)

Trapped solutions from wet process pretreatment represent a real concern. Even if effectively neutralized to be non-caustic, if they remain in a crevice or metal pore and the paint or powder coating is applied over them, there is a risk of their flashing to steam during a subsequent heating process, especially during the curing cycle for powder coating. Flashing to steam causes volume expansion, which can cause the coating to bubble and burst, leaving a blemished surface. The risk can be mitigated by hot air-drying between pretreatment and painting or powder coating.Nitriding Ferrous Panel Assemblies. Steel, stainless steel, or any other ferrous metal panel can be nitrided. Although nitriding is actually a form of case hardening, it is sometimes used as a means of applying a durable black surface finish.

Nitriding is a specialized form of heat treatment performed mostly by highly specialized shops. When the need arises to nitride an assembly, the fastener manufacturer should first be consulted about the fastener alloy and heat treatment. The information should then be provided to the nitriding shop (along with the panel alloy to determine if there is a process that will be compatible with both alloys).

If the alloys exhibit significantly different carbon content, the difference in critical temperatures may be a problem. The effect of nitriding on corrosion resistance of some stainless steel fastener materials also needs to be evaluated. Similarly, the effect of nitriding on the ductility of any ferrous fastener material should always be evaluated, as it typically has a negative effect.

While finishing a panel before installing self-clinching fasteners will always be the preferred process, these guidelines can help reduce inherent risks. There are many combinations of panel material, fastener material, and surface finish—even more than outlined here. Ultimately, the best practice is to consult the fastener manufacturer to ascertain the specific details on the fastener material and seek expert advice about the particular combination of finish and fastener, based on real-world experience. Surface finishers, too, can serve as key sources for technical information and relevant guidance.

| Commonly Cited Reasons for Surface Finishing a Panel Only After Self Clinching Fasteners Have Been Installed | Alternative Techniques Allowing for Panel Finishing Before Fastener Installation |

| To avoid damaging panel finish during fastener installation | Mitigate potential for panel damage by breaking sharp edges on all contact tooling (installation punches and anvils) and covering or radiusing all corners and edges of fastener feed tooling. Develop procedures for operating handling of panels. |

| Choose a more damage-resistant panel finish | |

| To achieve same appearance on panel and fasteners. Concern over variations in hue between zinc-plated panels and zinc-plated fasteners is common. | Ask the surface finisher who plates the panel to match the fastener. |

| Purchase unplated fasteners and have them plated by the panel surface finisher. | |

| Purchase unplated fasteners and have them plated by the panel surface finisher. | |

| To achieve a special purpose finish on the fastener. An example is a very specific color definition associated with a product brand | Ask the fastener manufacturer to supply the special purpose finish. |

| Ask the fastener manufacturer to supply the special purpose finish. | |

| Surface finish will make the outer surface of the panel too hard and/or too brittle for self-clinching. Examples include hard coat anodizing of aluminum panels or nitriding or other surface hardening of steel panels. | Mask the mounting hole ID and an annular ring around it on the side from which the fastener will be installed. |

| Mask the mounting hole ID and an annular ring around it on the side from which the fastener will be installed. | |

| Mask the mounting hole ID and an annular ring around it on the side from which the fastener will be installed. | |

| Mask the mounting hole ID and an annular ring around it on the side from which the fastener will be installed. | |

| Additive coating is too thick to allow full installation of the displacer component of the self clinching fastener. Examples include powder coating or very thick paint. | Mask the mounting hole ID and an annular ring around it on the side from which the fastener will be installed. |

| Purchase a special self-clinching fastener with an intentionally oversized displacer height | |

| Additive plating or coating is too brittle to deform without fracturing during fastener installation. Hardened electroless nickel plating is one example. | Mask the mounting hole ID and an annular ring around it on the side from which the fastener will be installed. |

| Thermally treat the coating to increase ductility. | |

| Choose a more ductile coating with similar corrosion resistance and appearance. |

BIORon Dise is Corporate Senior Technology Specialist at PennEngineering®, 5190 Old Easton Road, Danboro, PA 18916-1000 USA. Phone: 215-766-8853; Fax: 215-766-0143. He may be reached via email at rdise@pemnet.com. For more information, please visit www.pemnet.com.