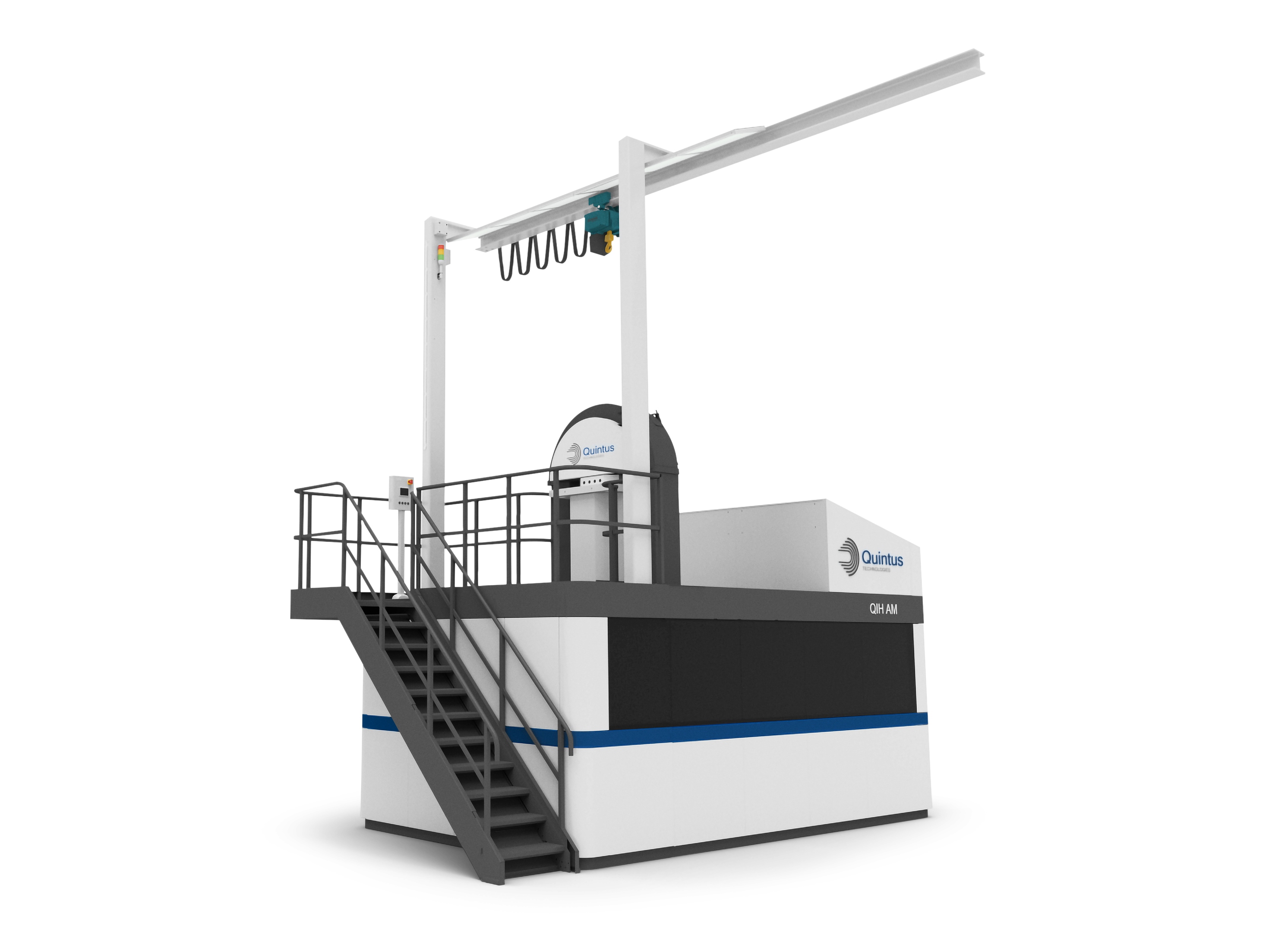

Quintus Technologies has introduced a new hot isostatic press (HIP) that it says could reduce the number of steps required in additive manufacturing (AM).

The QIH 60 M URC press includes the company’s uniform rapid cooling facility and combines heat treatment and cooling in a single high-pressure heat treatment (HPHT) process.

While HIPing is the standard method to eliminate pores and remove internal defects in metal and ceramic parts, the new press can also stress-relieve, heat treat, and age parts in one system, allowing manufacturers to consolidate several steps and remove discrete equipment from the production line, the company said.

The QIH 60 operates at a maximum temperature of 1400°C (2552°F) and pressure of 30,000 psi (2,070 bar) when using the molybdenum furnace. Graphite furnace options are also available for temperatures up to 2000°C (3632°F). The working dimensions of the vessel are 410 mm (in diameter and 1000 mm in height, with a capacity of 600 kg (1,322 lbs) per load.

This story uses material from Quintus, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.