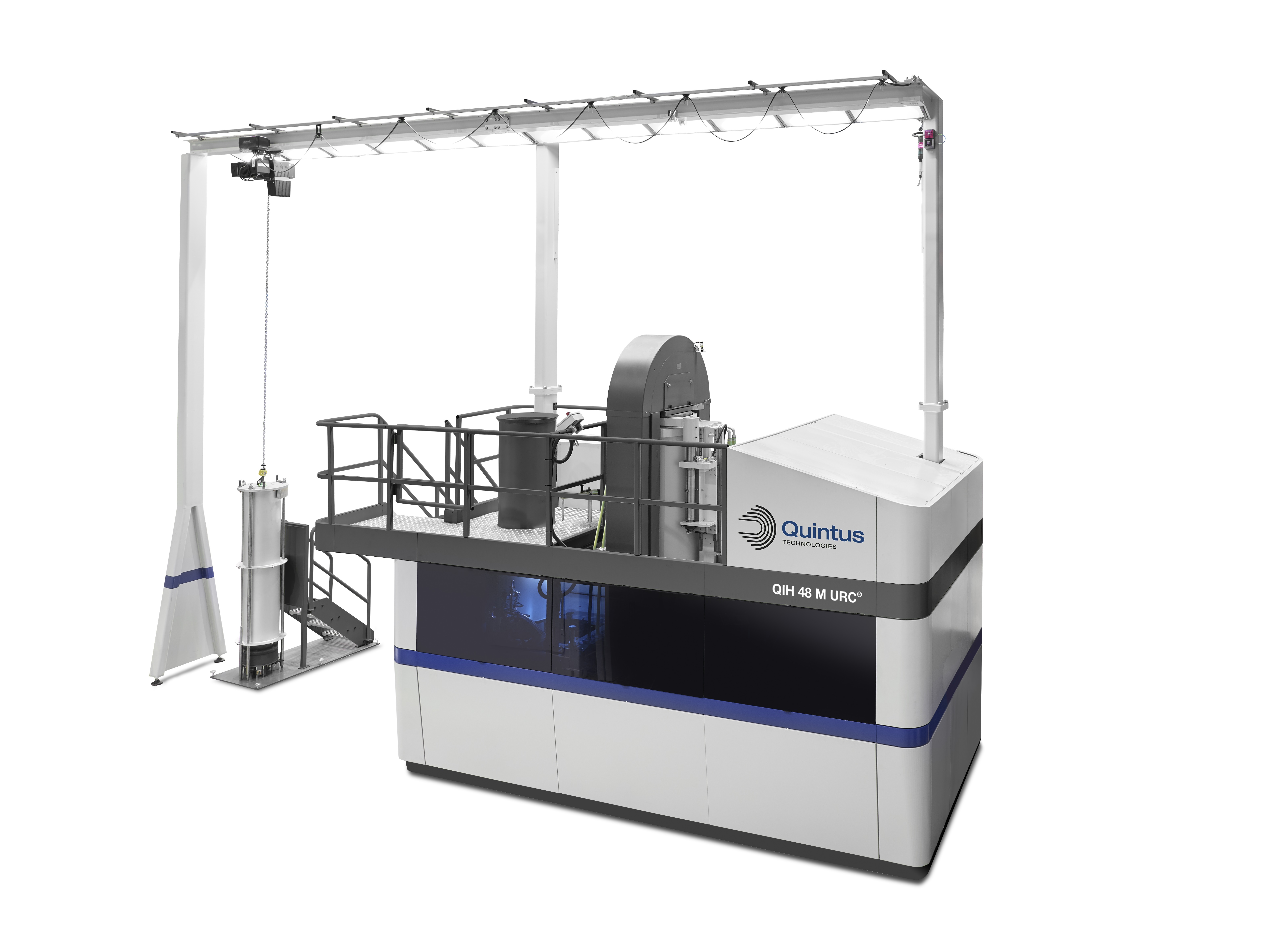

An additive manufacturing research facility based in Oregon, USA, has installed a QIH 48 M URC hot isostatic press (HIP) from Quintus.

The 30,000 ft2 facility is overseen by by Oregon Institute of Technology and, when open in late 2021, will develop new tools and techniques for the aerospace and defense, transportation, and metals sectors, Quintus said.

‘After evaluating the needs of the industry, we concluded that HIP and HPHT [high pressure, high temperature] would be critical sciences in the commercialization of additive manufacturing,’ said facility executive director Craig Campbell.

The press, which operates at a temperature of 2550°F (1400°C) and a pressure of up to 30,000 psi (2070 bar), will give researchers the ability to study densification of metals as well as how HPHT can modify the grain structure to enhance the mechanical properties of additively manufactured parts, he reported.

‘To conduct world-class, competitive research on new high-performance metal alloys, long-lasting tools, and rapid production of complex metal structures, especially in additive manufacturing, materials densification plays a pivotal role,’ added Dr Mostafa Saber, associate professor of at Oregon Tech.

This story uses material from Quintus, with editorial changes made by Materials Today.