Simufact Engineering has launched Simufact Additive software for the simulation of metal additive manufacturing processes.

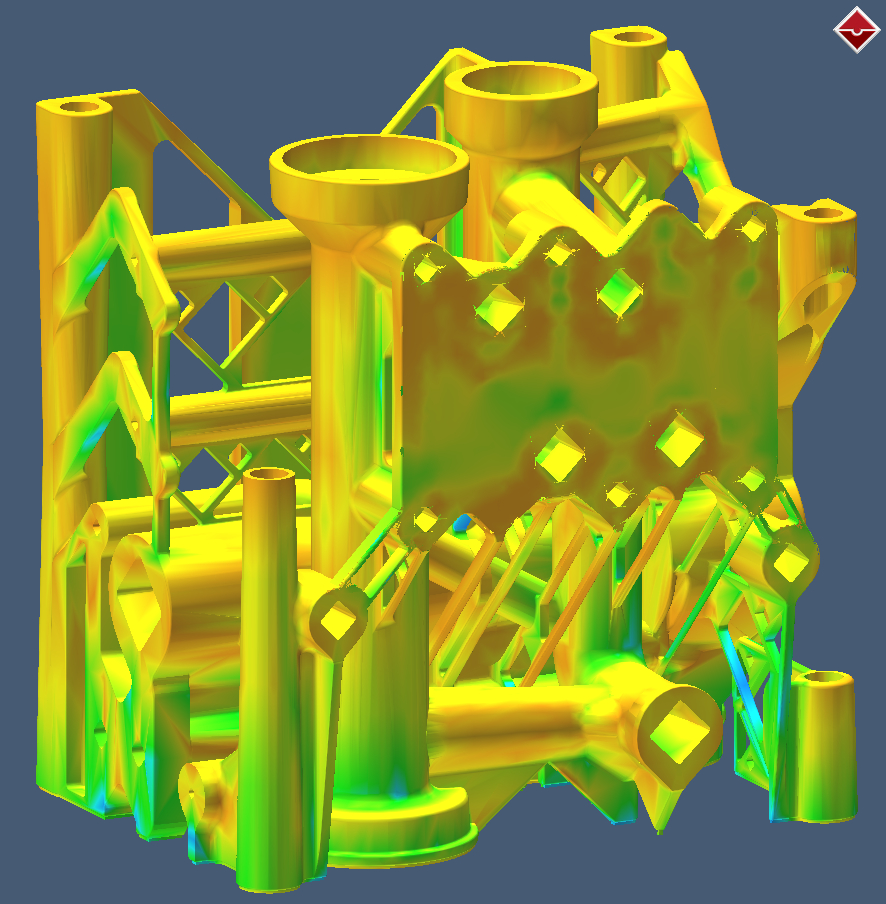

The software can simulate all key AM process steps starting with the ‘printing’ of the part, followed by heat treatment, cutting the part off the build plate and removal of support structures, plus heat and pressure combined processes, including hot isostalic pressing (HIP). The current version of Simufact Additive can predict the final distortion and residual stresses of metal 3D printed parts.

The modelling is carried out using CAD data in Graphical User Interface (GUI) environment aligned with the real process work flow. The software helps to compensate the distortion, minimize residual stresses and optimize the process parameters.

‘Today companies employing AM technology for printing metal parts have to cope with failure in their production processes and the high knock on costs associated with this,’ said Michael Wohlmuth, Simufact CEO. ‘Simufact Additive is an important tool which will help these companies get it ‘right first time’, by regularly running simulations prior to production.’

This story is reprinted from material from Simufact, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.