Burloak Technologies, based in Canada, has acquired a hot isostatic press (HIP) to help scale up its production of 3D printed parts.

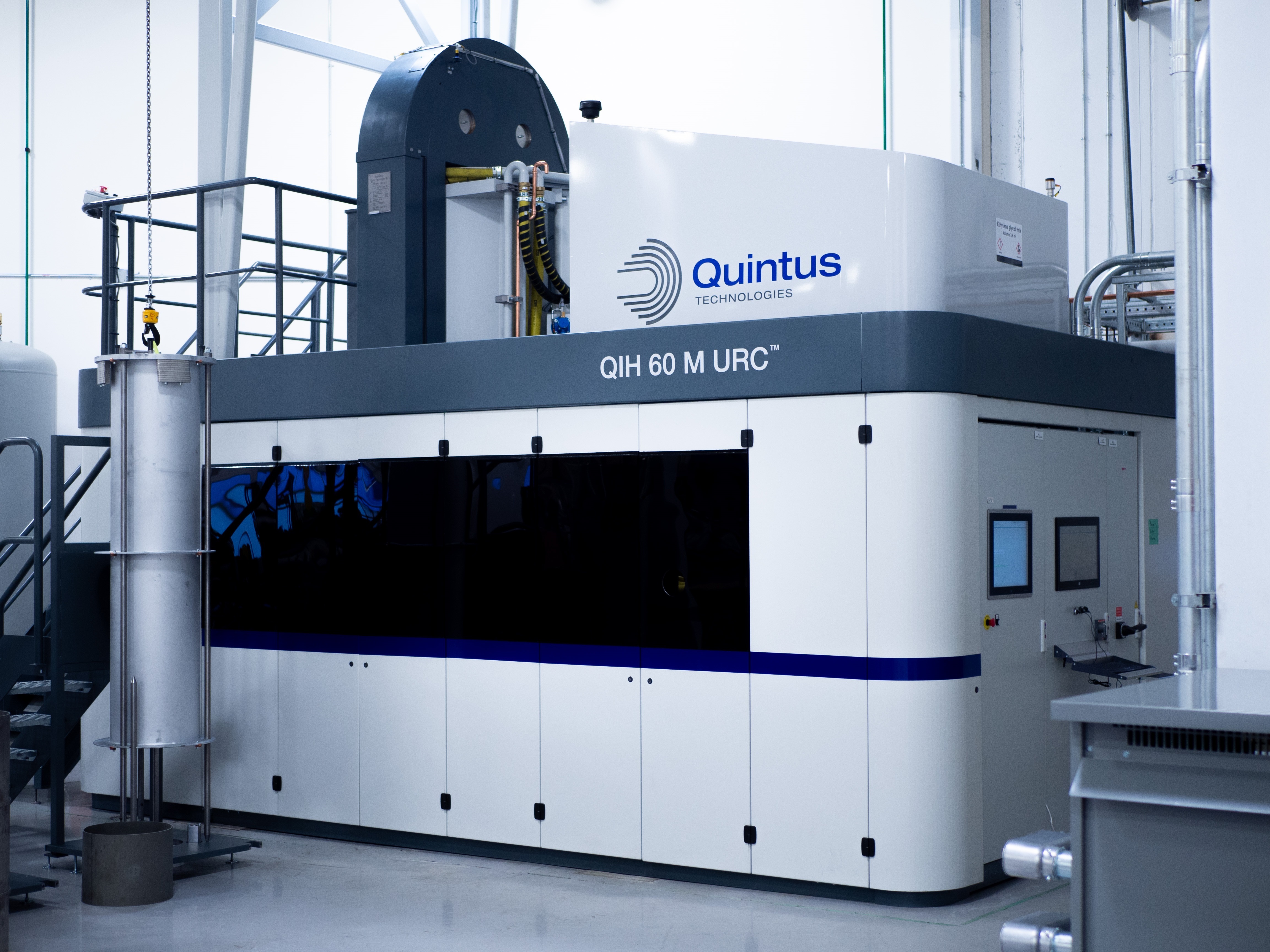

The QIH 60 M URC HIP made by Quintus Technologies, incorporates high pressure, heat treatment, and cooling in a single process, making it possible to remove several operations from the AM production line, Quintus said, The HIP can reach a peak gas cooling rate of > 1500K/min and the cooling cycle can be programmed to stop at a specific temperature while maintaining the desired pressure set point, according to Quintus. Rapid cooling under pressure can minimize thermal distortion and non-uniform grain growth in components, producing more finished parts and allowing Burloak to increase production.

‘This capability is critical for Burloak as a full-service supplier for all customers, and, in particular, for the development of high-strength flight components,’ said Peter Adams, CIO. ‘Without this in-house capability, outsourcing this process would slow down our project timelines, add complexity to our processes, and risk damaging critical customer components as they would need to be shipped internationally.’

This story uses material from Quintus, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.