Most of today's batteries utilize rare lithium mined from the mountains of South America. If this source becomes depleted, then battery production could stagnate. Sodium is a very cheap and earth-abundant alternative to the lithium in batteries, but is also known to turn purple and combust if exposed to water – even just water in the air.

Worldwide efforts to make sodium-ion batteries just as functional as lithium-ion batteries have long since controlled sodium's tendency to explode, but have not yet resolved how to prevent sodium ions from ‘getting lost’ when a sodium-ion battery is initially charged and discharged. Now, researchers at Purdue University have developed a form of sodium powder that fixes this problem and holds a charge properly.

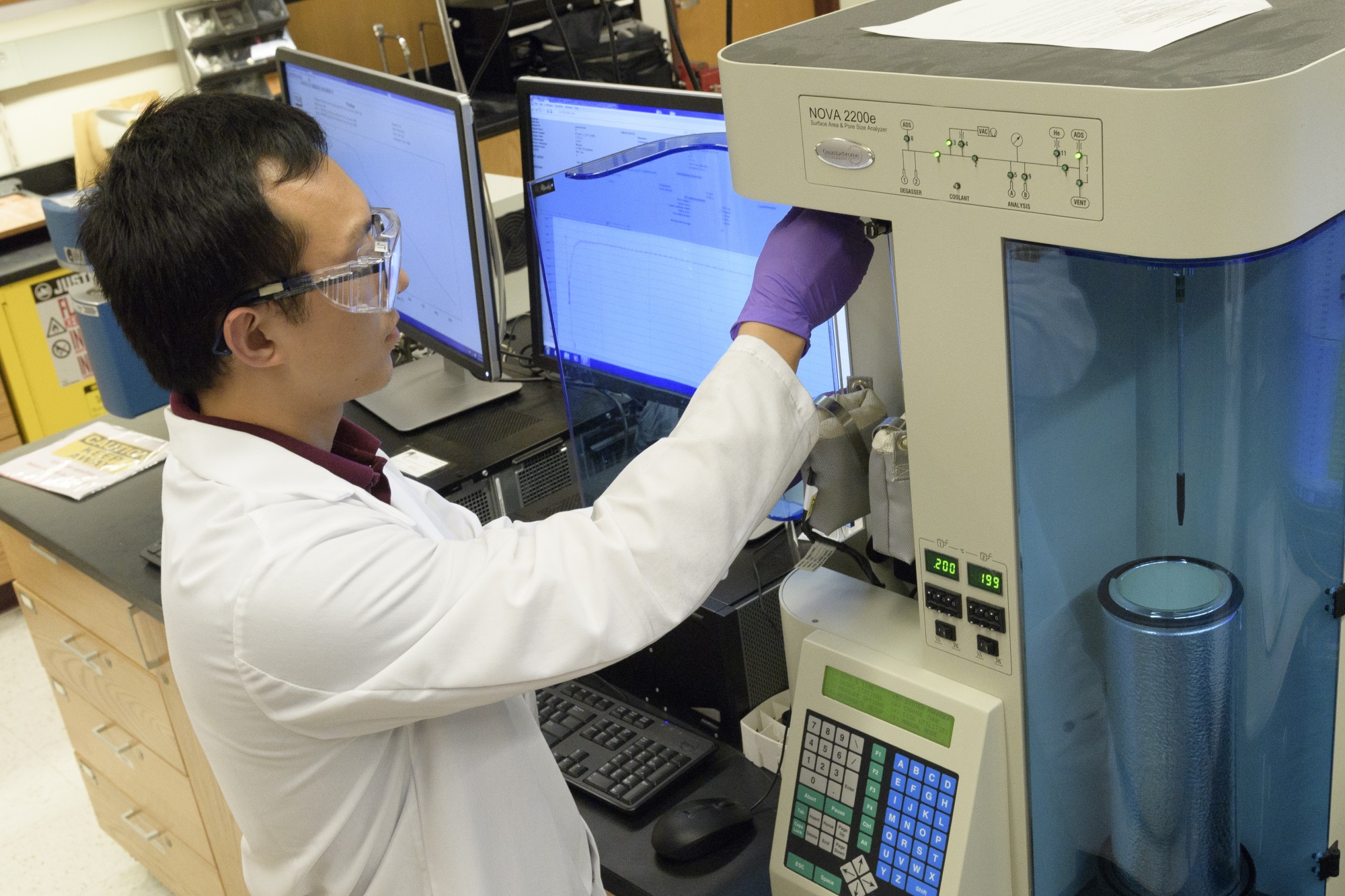

"Adding fabricated sodium powder during electrode processing requires only slight modifications to the battery production process," said Vilas Pol, associate professor of chemical engineering at Purdue University. "This is one potential way to progress sodium-ion battery technology to the industry." The researchers report their work in a paper in the Journal of Power Sources.

Even though sodium-ion batteries would be physically heavier than lithium-ion batteries, researchers have been investigating them because they could potentially store the energy generated by large solar and wind power facilities at lower cost. The problem is that sodium ions tend to stick to the carbon-based anode in the battery during the initial charging cycles, preventing the ions from traveling over to the cathode. The ions build up into a structure called a ‘solid electrolyte interface’.

"Normally the solid electrolyte interface is good because it protects carbon particles from a battery's acidic electrolyte, where electricity is conducted," Pol explained. "But too much of the interface consumes the sodium ions that we need for charging the battery."

The Purdue researchers proposed using sodium as a powder, which provides the required amount of sodium for the solid electrolyte interface to protect the anode but doesn't build up in a way that consumes sodium ions.

They minimized sodium's exposure to the moisture that would make it combust by making the sodium powder in a glovebox filled with the gas argon. Using ultrasound, they melted sodium chunks to form a milky purple liquid, which they cooled into a powder and then suspended in a hexane solution to evenly disperse the powder particles.

Just a few drops of this sodium suspension on the anode or cathode during their fabrication allows a sodium-ion battery cell to charge and discharge with more stability and at higher capacity – the minimum requirements for a functional battery.

This story is adapted from material from Purdue University, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.