SLM Solutions says that its NXG XII 600 metal 3D printer can be used to manufacture parts for powertrain applications such as such as E-drive housings, cylinder blocks and cylinder heads.

SLM’s NXG XII 600 is equipped with twelve overlapping 1 kW lasers and a build envelope of 600x600x600 mm, enabling the production of large-volume square parts with up to 120 µm layer thickness or more, the company said. It also features variable beam spot, bi-directional recoating, laser balance and an improved gas flow.

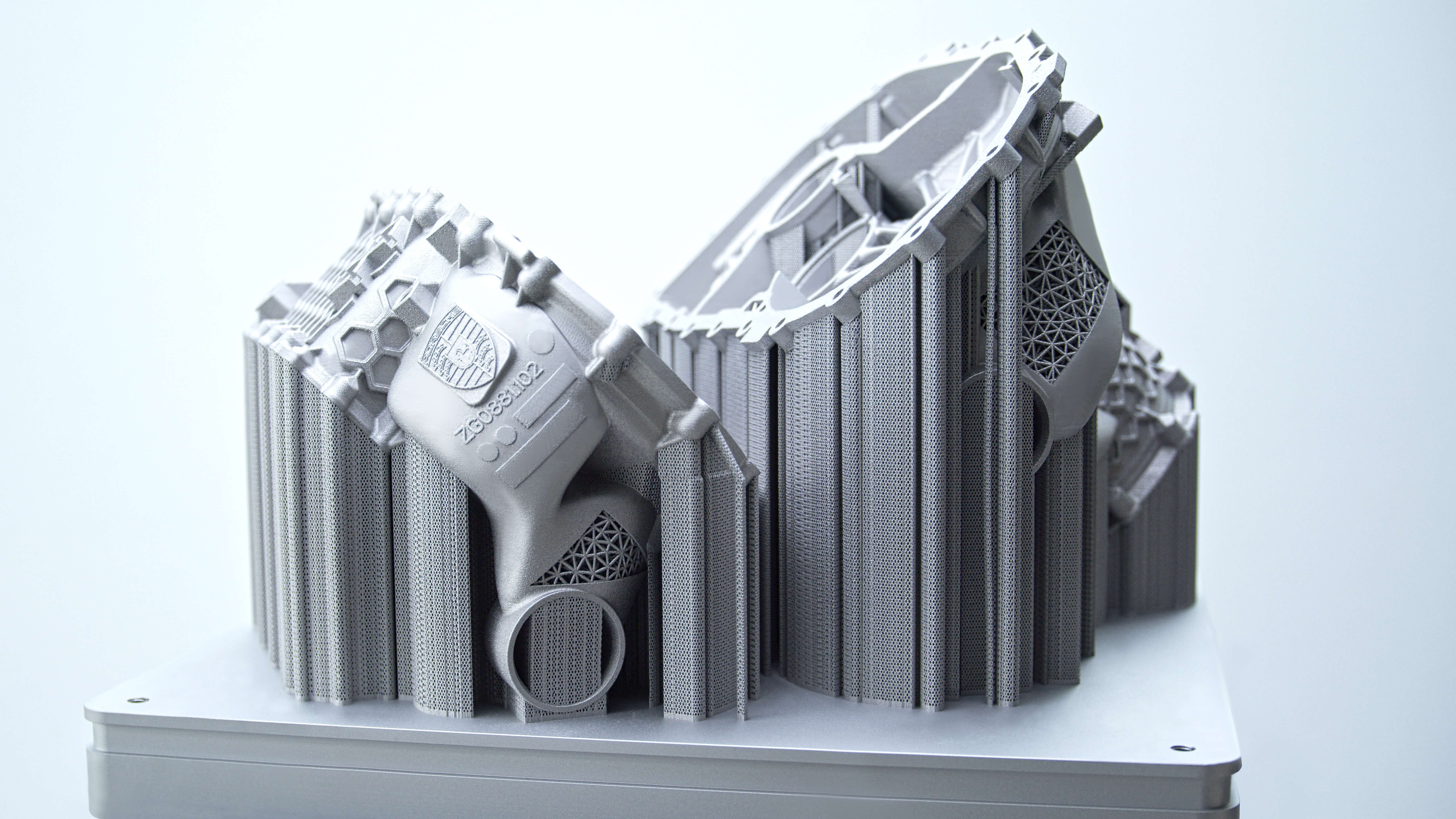

According to the company, it recently printed a complete E-drive housing for a Porsche sports car, featuring an integrated downstream two-stage transmission for drivinh the wheels with up to 2,100 Newton meters of torque. The housing, which is designed for use on the front axle of a sports car, features lattice structures to reduce the weight, functional integration of cooling channels, higher stiffness, better integration of parts and improved part quality, SLM says. The E-drive unit measures 590 x 560 x 367 mm and was built in 21 hours.

‘This new manufacturing technology is technically and economically interesting for us,’ said Falk Heilfort, powertrain development engineer at Porsche. ‘Possible use cases are especially prototypes in the development phase, special and small series production as well as for motor sport and classic spare parts.’

This story uses material from SLM, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.