Additive manufacturing (AM) techniques featuring atomic precision could one day create materials with increased flexibility and toughness, according to researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL).

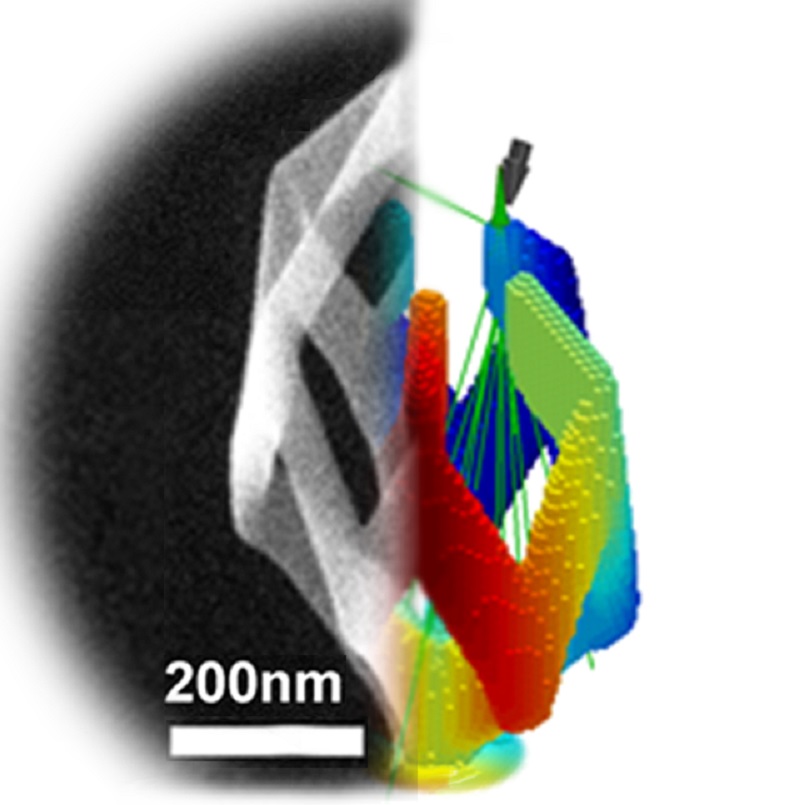

In a review paper published in the American Chemical Society’s Nano journal, ORNL researcher Olga Ovchinnikova and colleagues suggest that the ultimate goal of AM is to create and customize material at the atomic scale. Material could be assembled atom by atom, using a concept known as directed matter. This could lead to virtually perfect materials and products because many limitations of conventional manufacturing techniques would be eliminated.

‘Being able to assemble matter atom by atom in 3D will enable us to design materials that are stronger and lighter, more robust in extreme environments and provide economical solutions for energy, chemistry and informatics,’ said Ovchinnikova.

Directed matter also eliminates the need to remove unwanted material by lithography, etching or other traditional methods.

The paper is entitled ‘Directing Matter: Towards Atomic Scale 3D Nanofabrication’.

This story is reprinted from material from Oak Ridge, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.