Oak Ridge National Laboratory (ORNL) says that it has 3D printed parts for a nuclear plant in Alabama, USA.

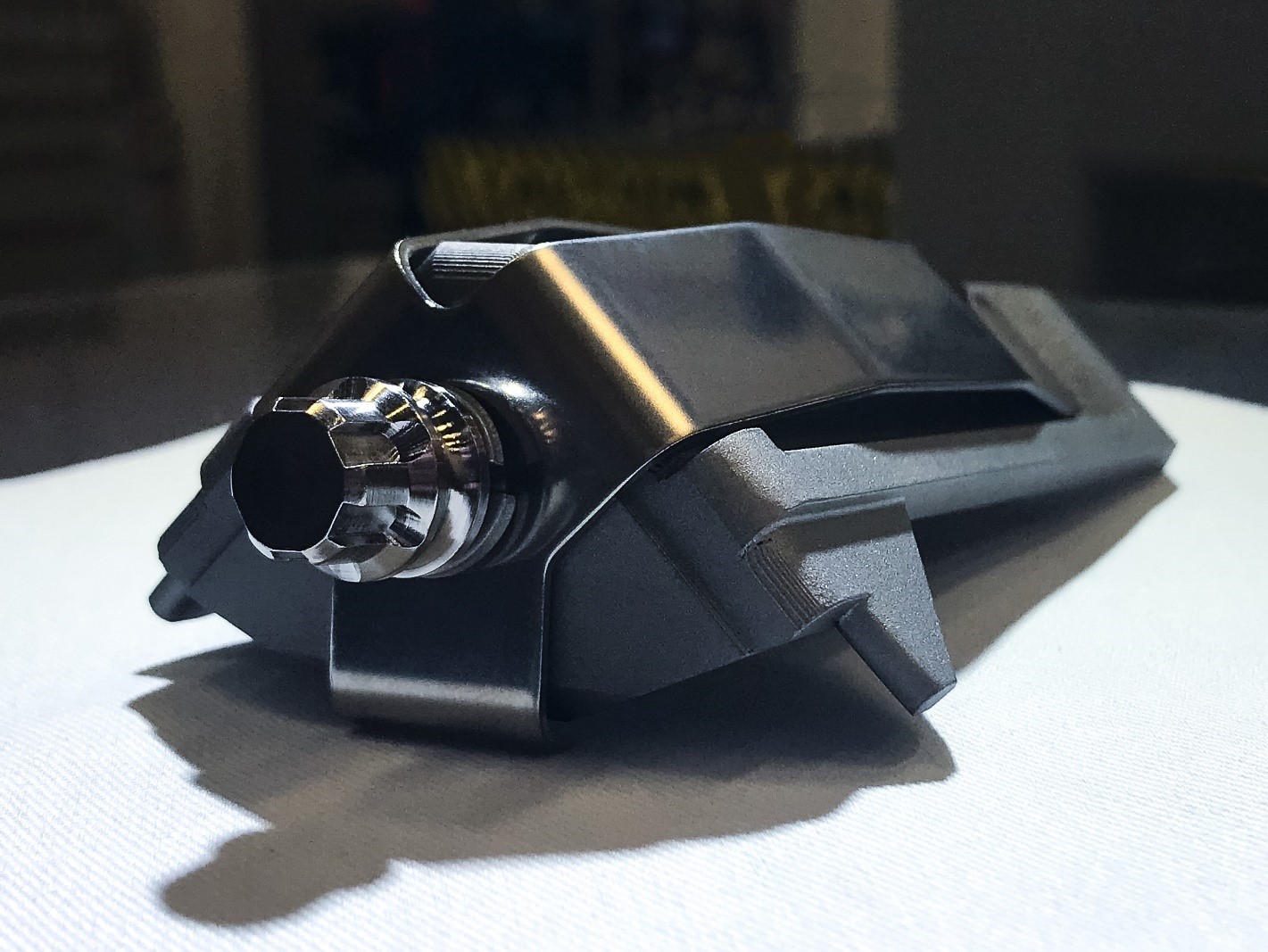

The channel fasteners for a boiling water reactor fuel assembly were developed by plant operator TVA, French nuclear reactor company Framatome and the US Department of Energy (DoE).

According to the companies, the parts required a straightforward, non-symmetric, geometry that could be made using additive manufacturing (AM).

ORNL plans to extend the viability and operations of US nuclear power plants and deploy new nuclear power technologies.

‘Collaborating with TVA and ORNL allows us to deploy innovative technologies and explore emerging 3D printing markets that will benefit the nuclear energy industry,’ said John Strumpell, manager at at Framatome. ‘This project provides the foundation for designing and manufacturing a variety of 3D printed parts that will contribute to creating a clean energy future.’

‘Deploying 3D-printed components in a reactor application is a great milestone,’ added ORNL program director Ben Betzler. ‘It shows that it is possible to deliver qualified components in a highly regulated environment.’

This story uses material from Oak Ridge, with editorial changes made by Materials Today.