Diesel engine maker Cummins Inc is working with Oak Ridge National Laboratory to develop a material to repair heavy-duty vehicle engines.

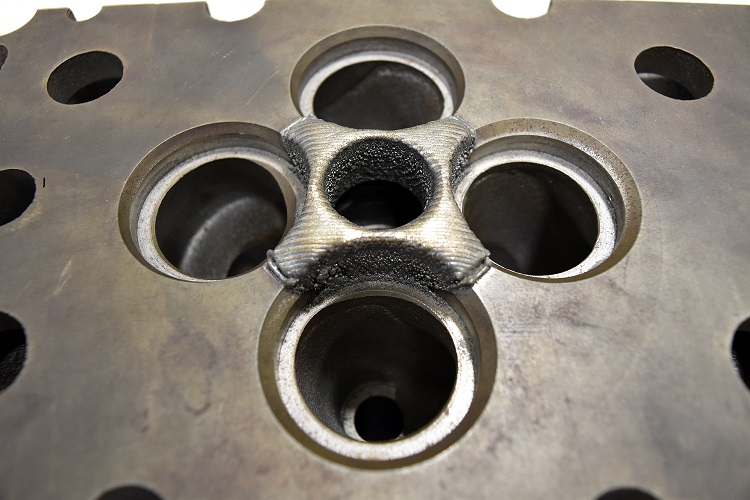

According to Oak Ridge, the engines could be damaged by a million miles of extreme conditions under the hood. Rather than replacing an engine’s cylinder head, the research team scooped out the worn section and used additive manufacturing (AM) to deposit a high-performance alloy.

The researchers say that the repair material was better than the original casting.

The goal of the process, developed at the US Department of Energy’s manufacturing demonstration facility at ORNL, is to save energy while extending the life of the engine and making it stronger.

‘We’re decreasing the engine’s thermal conductivity, which holds heat in longer, and turning it into increased efficiency,’ said Nikhil Doiphode, Cummins’ parts R&D engineer. ‘While these are not brand-new engines, we’re striving to make them better than new.’

This story is reprinted from material from Oak Ridge, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.