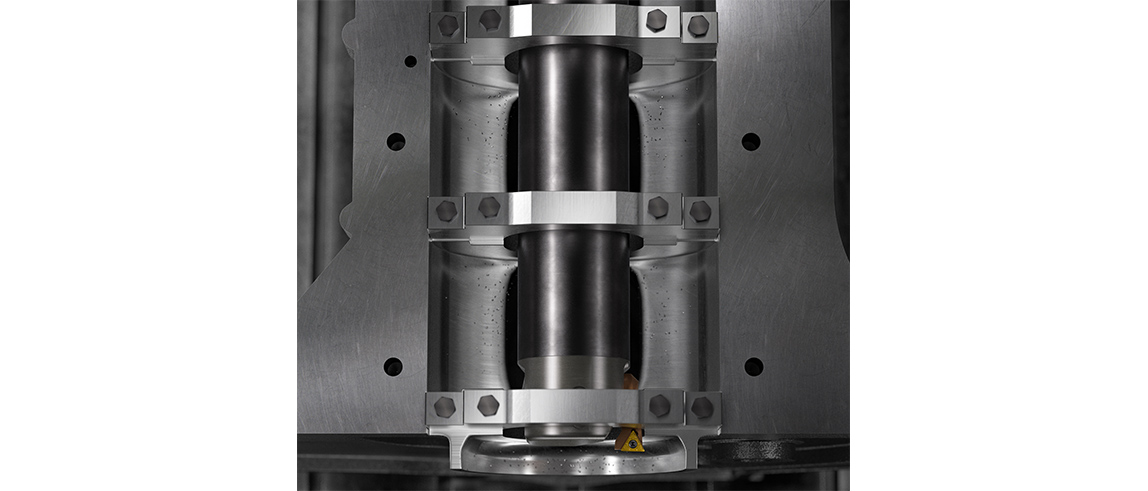

Cutting tool specialist Sandvik Coromant has released a new version of its CoroBore 825 damped fine-boring tool. The system reportedly makes use of the company’s Silent Tools technology, with dampers dimensioned to suit adaptor size in the assortment. Sandvik says that this can improve productivity as cutting data can be increased.

The new tool has a change of boring head material from steel to aluminium, and the head has been shortened so that the damper comes closer to the cutting edge.

'Internal channels are utilised to deliver coolant directly to the cutting edge, which is another factor that contributes to improved surface finish, higher penetration rates and greater process security,' said Jenny Nilsson, global product manager at Sandvik Coromant.

The CoroTurn insert carriers for the new tools have entering angles at 92-95°, making it possible to approach the bottom of a blind hole without engaging a bigger part of the cutting edge, according to the company.

CoroBore 825 is suitable for all fine-boring applications, covering diameters from 19 to 167 mm (0.748 to 6.575 inch), while a new assortment of cartridges can be utilized for back-boring applications. During back boring, the same internal coolant flow to the cutting edge is offered as with conventional boring.

This story uses material from Sandvik Coromant, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.