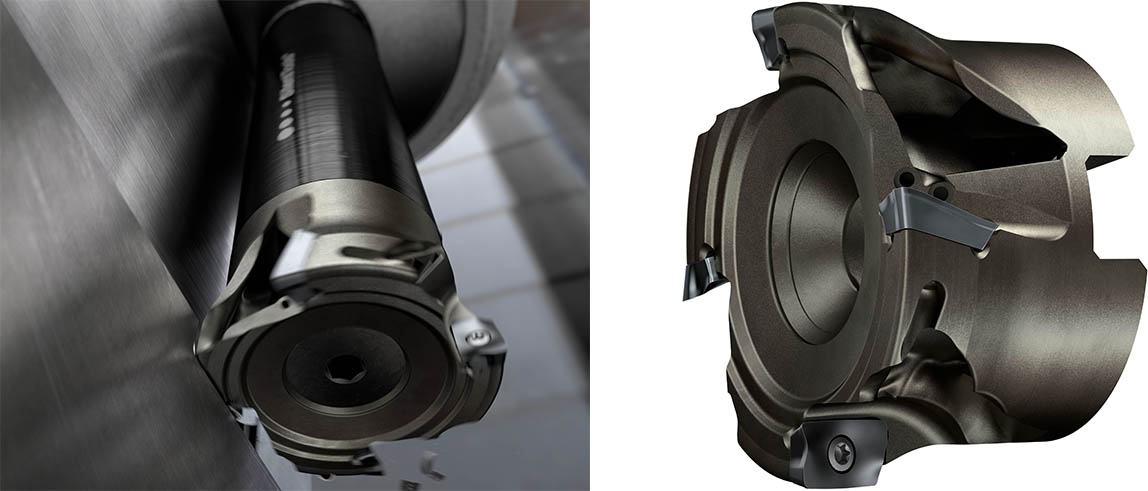

Cutting tool and tooling system specialist Sandvik Coromant has developed a version of its CoroMill 390, featuring a titanium alloy cutter body produced using additive manufacturing (AM). The company says that the lighter overall weight of the tool can help minimize vibration and improve security during machining with long overhang.

In tookmaking, AM allows for the generation of shapes and features not possible with metal cutting, according to Magnus Engdahl, product application manager. ‘When designing our new lightweight CoroMill 390, material has been tactically removed to create the optimal cutter design for minimizing mass. This is called topological optimization and it makes the cutter more compact and significantly lighter than a conventional version, thus helping machine shops to boost the productivity of their long-overhang milling operations. Moreover, a shorter distance between the damper in the adaptor and the cutting edge improves performance and process security.’

According to Engdahl, process security is important in a number of metal-cutting applications, especially when milling with long overhangs, which is a common requirement in components used by the aerospace and oil and gas sectors. Here, making features such as deep cavities can be compromised by vibration, leading to slower production, shorter tool life and poor surface finish.

This story uses material from Sandvik Coromant, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.