Betatype has developed Engine for AM, a CAD/CAM program which can help design, implement and manufacture complex geometries through additive manufacturing (AM).

The company says that the technology can simplifying the representation of complex geometries and aid the translation of complex geometries to toolpaths for both generic and specific AM processes.

Engine could make the task of designing complex geometry easier for the designer by removing the need to create a solid mesh. By using an abstracted representation, the complexity and file size of CAD data is reduced and more manageable, Betatype says.

The company has developed a new open format, ARCH, that contains both geometry and process specific parameters that can be exported from CAD packages through plugins, or written by writing directly. Engine converts ARCH data into a range of general and specialised toolpaths that have been developed by Betatype for industrial AM processes. It can generate both generic (.cli) and specific machine formats. Combined with material calibration, Engine can provide higher detail and faster build times than with current standard approaches, Betatype reports.

The software has been tested across a growing range of selective laser melting (SLM) based systems to determine compatibility.

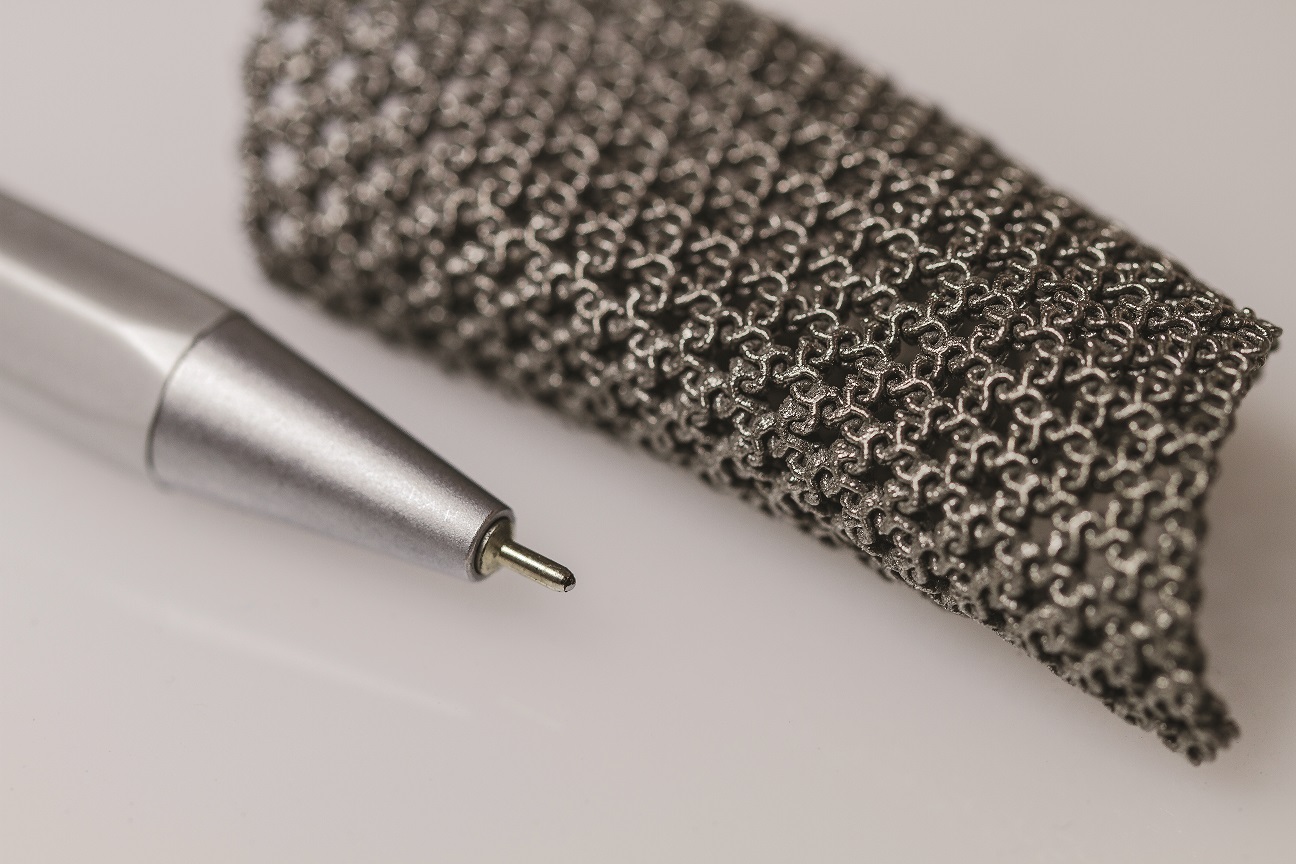

Engine is additionally a platform for Betatype’s architectured materials library, enabling users to simply drag and drop a range of materials onto volumetric CAD designs.

This story is reprinted from material from Betatype, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.