The Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) says that it has successfully processed a new type of iron powder for additive manufacturing (AM).

With the newly tested production method, prices for iron powder can be achieved of around 10% of current costs, IFAM says. The method can also produce cheaper hydride-dehydride (HDH) titanium powder.

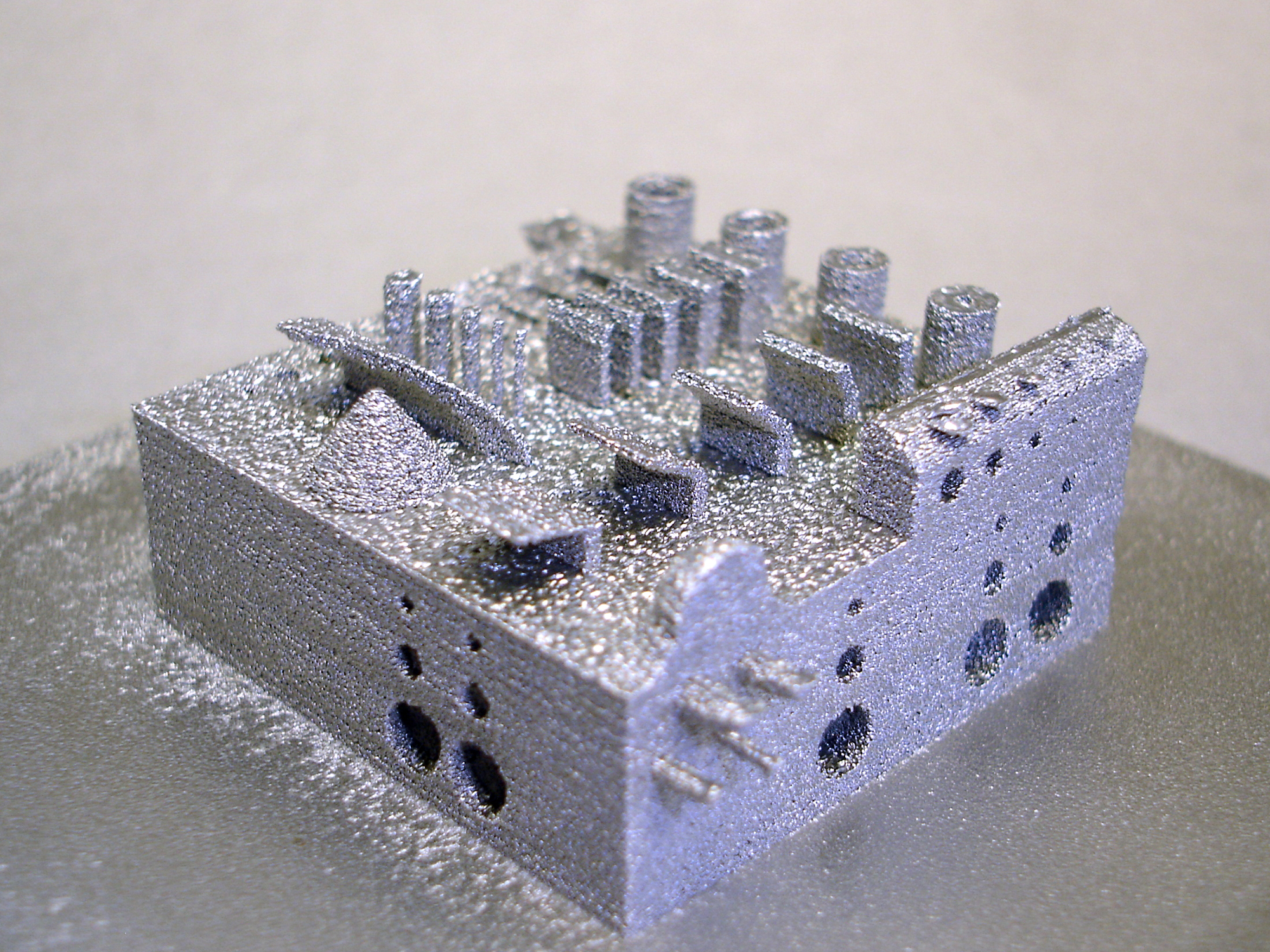

Previously, only spherical powders produced by inert gas atomization have been used for additive manufacturing using selective electron beam melting (SEBM) and selective laser melting (SLM), the institute claims. However, using powder containing more irregular particle shapes in the SEBM process can be a ‘very robust technology’ with regard to variations in the flowability of the powder.

Using various powder mixtures for the processing of a wide variety of alloys have also been successfully tested, IFAM says.

This story uses material from Fraunhofer, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.