Aluminum specialist Eck Industries has signed a licence for the commercialization of a cerium-aluminum (Ce-Al) alloy co-developed by the Department of Energy’s Oak Ridge National Laboratory.

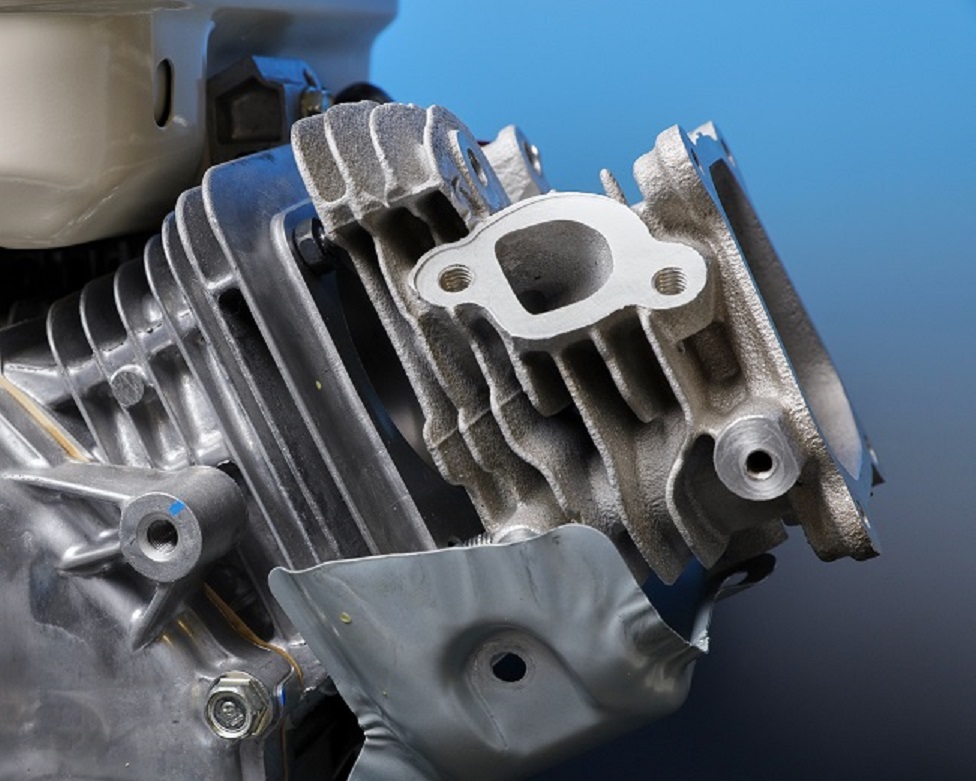

The alloy is reportedly suitable for creating lightweight, strong components for vehicles and aircraft. The Ce-Al alloy is also corrosion-resistant and in tests is stable at 500°C. Withstanding higher temperatures means that engines made using the alloy can run hotter with more complete fuel combustion while being lighter in weight, which advances fuel efficiency.

Cerium makes up as much as half of mined rare earths, yet has less value than co-mined elements like neodymium and dysprosium that are in high demand for advanced energy technology applications. Creating new uses for cerium supports domestic rare earth mining operations and the US manufacturing sector, according to Oak Ridge

Casting with the alloy can be accomplished using standard aluminum foundry practices and without a protective atmosphere.

‘There has been tremendous interest from industry due to the unique material properties and low cost of this alloy,’ said David Weiss, vice president of engineering/R&D at Eck. ‘This project is a template for rapid development and commercialization.’

This story is reprinted from material from ORNL, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.