Researchers at the University of Pennsylvania have developed a process that could make it easier to recycle neodymium and dysprosium.

In contrast to the massive and energy-intensive industrial process currently used to separate rare earths from end products, the Penn team’s method works nearly instantaneously at room temperature and uses standard laboratory equipment.

Sourcing neodymium and dysprosium from used electronics rather than the ground would also increase their supply.

Neodymium magnets can give you the strongest amount of magnetism for the smallest amount of stuff and can perform at a range of temperatures. These thermal qualities are achieved by mixing neodymium with other elements, including the rare-earth metal dysprosium, in different ratios. Because those ratios differ based on the application the magnet is being used for, the two metals need to be separated and remixed before they can be reused.

Currently, whether purifying the neodymium and dysprosium out of minerals or out of an old power tool motor, the same energy-intensive process is used. The technique, known as liquid-liquid extraction, involves dissolving the composite material and chemically filtering the elements apart. The process is repeated thousands of times to get useful purities of the rare-earth metals, and so it must be conducted on an industrial scale.

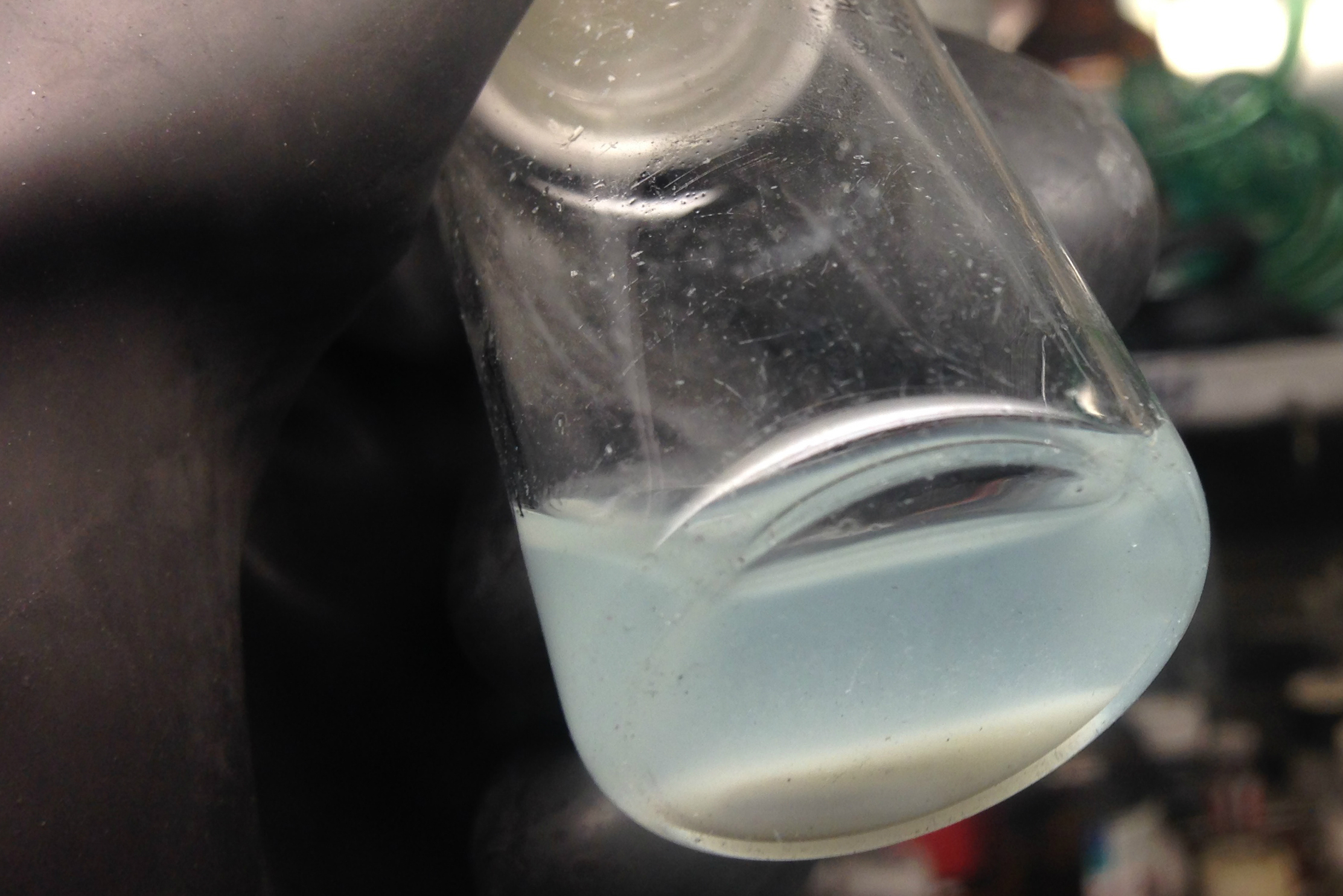

Rather than this liquid-liquid method, Schelter’s team has devised a way to separate the two metals by selectively dissolving the neodymium in a solution and leaving behind the dysprosium as a solid. This method has allowed the researchers to separate equal mixtures of the metals into samples that are reportedly 95% pure.

Separation problem

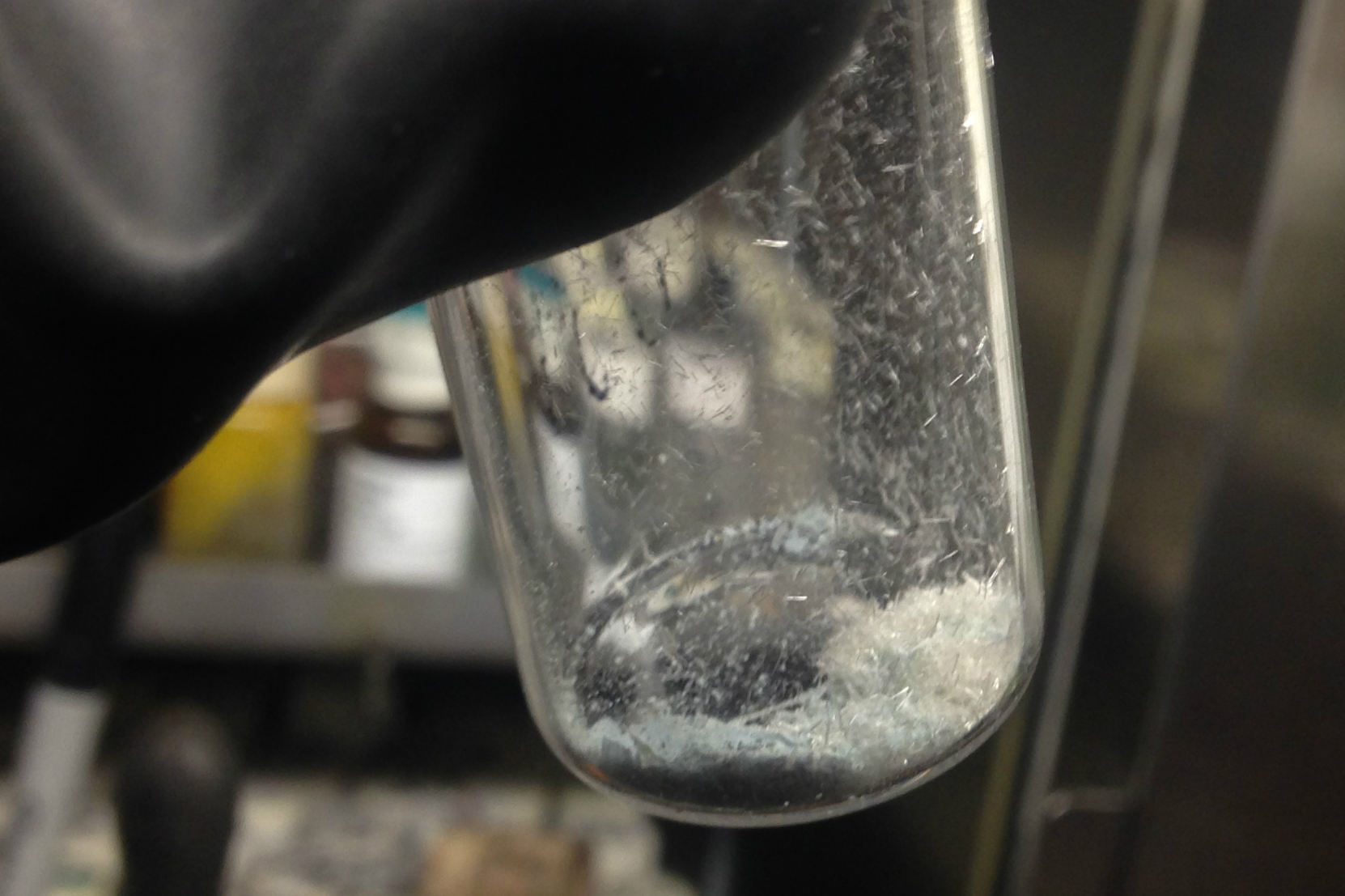

Starting with the two elements as a mixed powder, a metal-binding molecule known as a ligand is applied. The type of ligand the research team designed has three branches, which converge on the metal atoms and hold them in the aperture between their tips. Because of neodymium’s slightly larger size, the tips don’t get as close together as they do around dysprosium atoms.

‘The difference in size between the two ions is not that significant, which is why this separation problem is difficult,’ said Eric J. Schelter, assistant professor in the Department of Chemistry in Penn’s School of Arts & Sciences, ‘But it’s enough to cause that aperture to open up more for neodymium. And, because it is more open, one ligand-neodymium complex can combine with another, and that really changes its solubility.’

The combination of the two neodymium complexes, known as a dimer, encapsulates the neodymium ions, enabling them to dissolve in solvents like benzene or toluene. The dysprosium complexes do not dissolve, enabling the two metals to be easily separated. Once apart, an acid bath can strip the ligand off both metals, enabling it to be recycled as well.

‘If you have the right ligand, you can do this separation in five minutes, whereas the liquid-liquid extraction method takes weeks,’ Schelter said. ‘A potential magnet recycler probably doesn’t have the capital to invest in an entire liquid-liquid separations plant, so having a chemical technology that can instantaneously separate these elements enables smaller scale recyclers to get value out of their materials.’

Future work will involve improving the stability of the ligand so it is less likely to fall off before the metals are separated. Further modification of the ligand could enable other rare earths in technology products, such as compact fluorescent light bulbs, to be recycled this way.

The research was published in Angewandte Chemie, International Edition.

This story is reprinted from material from the University of Pennsylvania, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.