Manufacturing consultant EWI has selected Granta’s MI software to better coordinate its additive manufacturing (AM) work across multiple additive manufacturing (AM) platforms, according to the software provider.

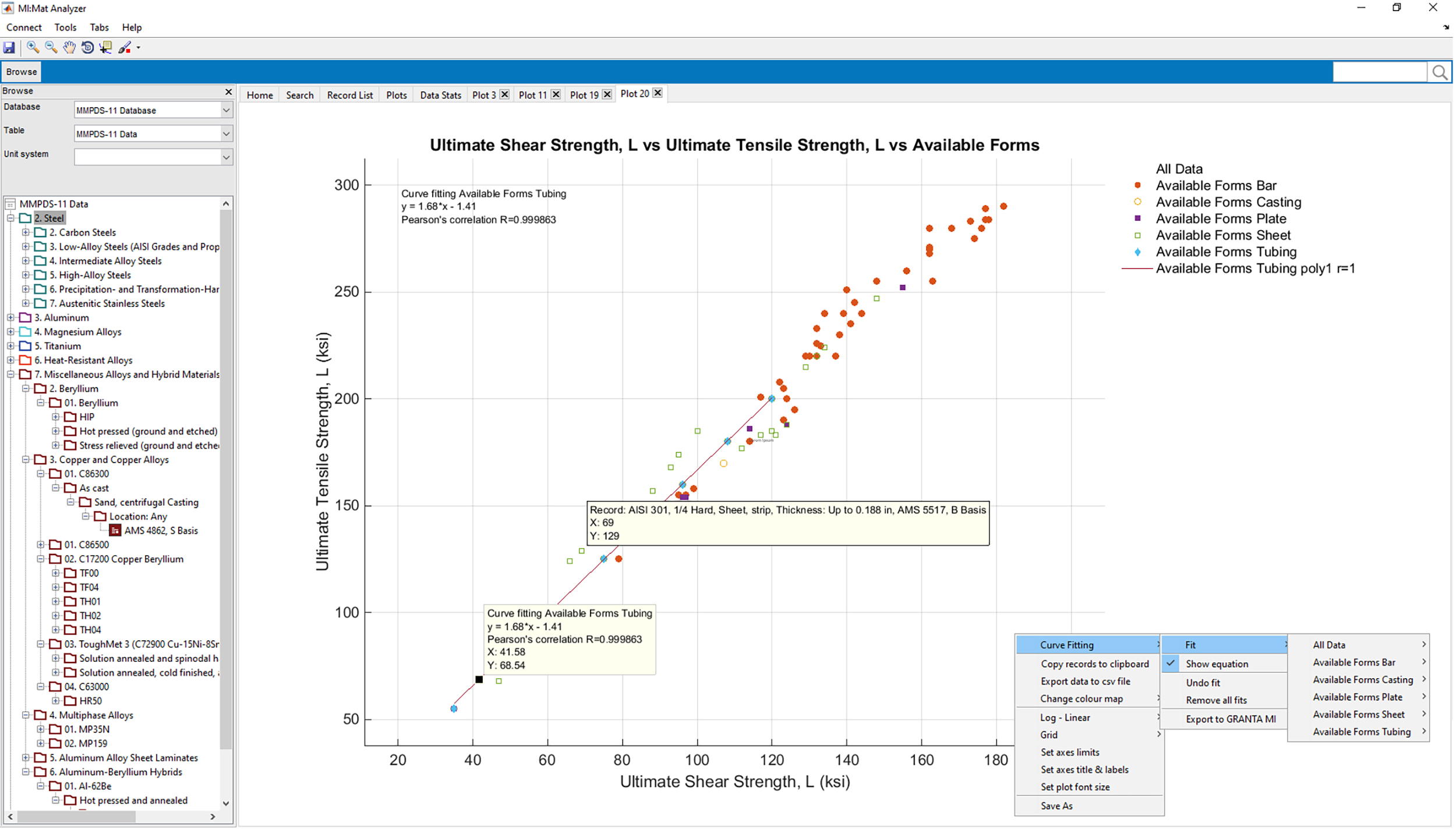

Granta MI uses apps and tools to capture and re-use materials data and supports CAD, CAE and PLM.

According to Granta, defining a strategy to capture and characterize material information across different AM platforms can be a challenge, as every AM machine monitors different metrics and exports data differently. The software can help define the most effective way to record the data, and then automate and control the input process.

‘This data capture will allow us to make valuable correlations that can be used to generate data driven standards across the industry, and streamline the development of AM parts internally,’ said Brendan Lewis, EWI project engineer.

EWI is also working with ASTM on a variety of programs to generate data for standards development.

This story uses material from Granta,with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.