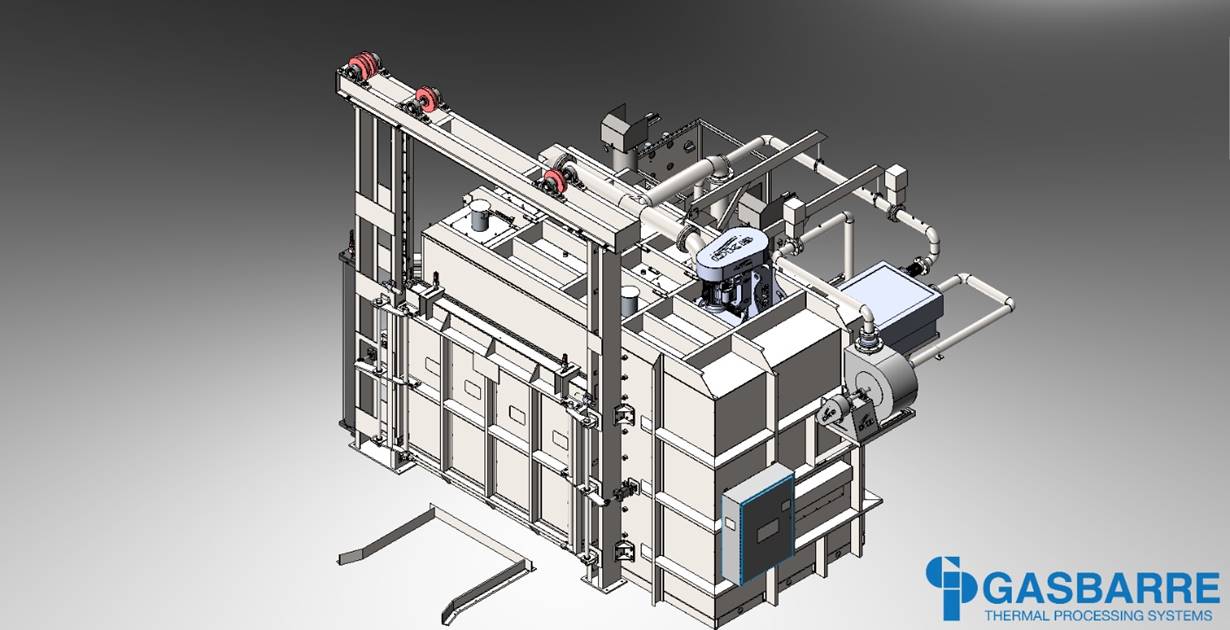

Gasbarre Thermal Processing Systems says that it has built an atmosphere tempering furnace for an aerospace market manufacturer with captive heat-treating capabilities.

The furnace has a working load size of 84’ wide, 42’ deep, and 60’ tall and a max load weight of 6,000 pounds, and can operate between 350? to 1600?, the company said. It also passes uniformity at +/- 10? per AMS2750E and is equipped with custom controls including Eurotherm brand temperature controlling instrumentation, an Allen-Bradley PLC and HMI. Automatic atmosphere control is included for running under Nitrogen, Argon, and/or a Hydrogen blend. Custom designed atmosphere cooling systems are installed to reduce overall cycle time.

According to Gasbarre, the equipment configuration enabled the customer to switch from pit furnace style processing, which eliminated infrastructure costs and maintenance concerns.

This story uses material from Gasbarre, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.