Scientists at Georgia Tech Research Institute in the US have been researching using metal 3D printing to improve golf putters.

Plans are to develop a way for golfers to adjust parts of their club to find a better stroke, rather than having to buy a new club.

According to the researchers, a putter’s center of gravity affects how the clubhead moves during a stroke. The idea is to hit the ball with the putter’s face squared up, but every golfer’s stroke is different, and most rotate the face during their swing. Changing the density of the party could improve the directional control of the ball.

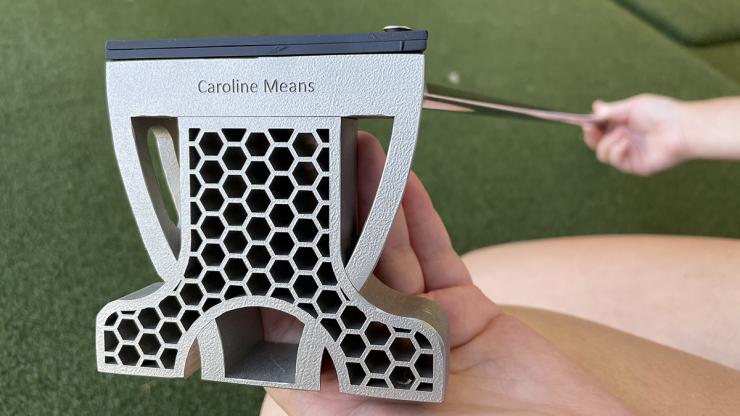

The team have developed a prototype putter made with stainless-steel powder, using a 3D printer generally used to make aircraft parts.

‘The 3D printing in collaboration with mechanical engineering associate professor Chris Saldana gives us an advantage to create structures that could not be machined through traditional methods,’ said Caroline Means, project designer. ‘That means that after it's been manufactured, a golfer can pick what face surface material they want for the putter.’

This story uses material from Georgia Tech, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.