Metalysis Ltd reports that it has successfully produced graphene using the company’s proprietary electrochemical metal powder manufacturing process.

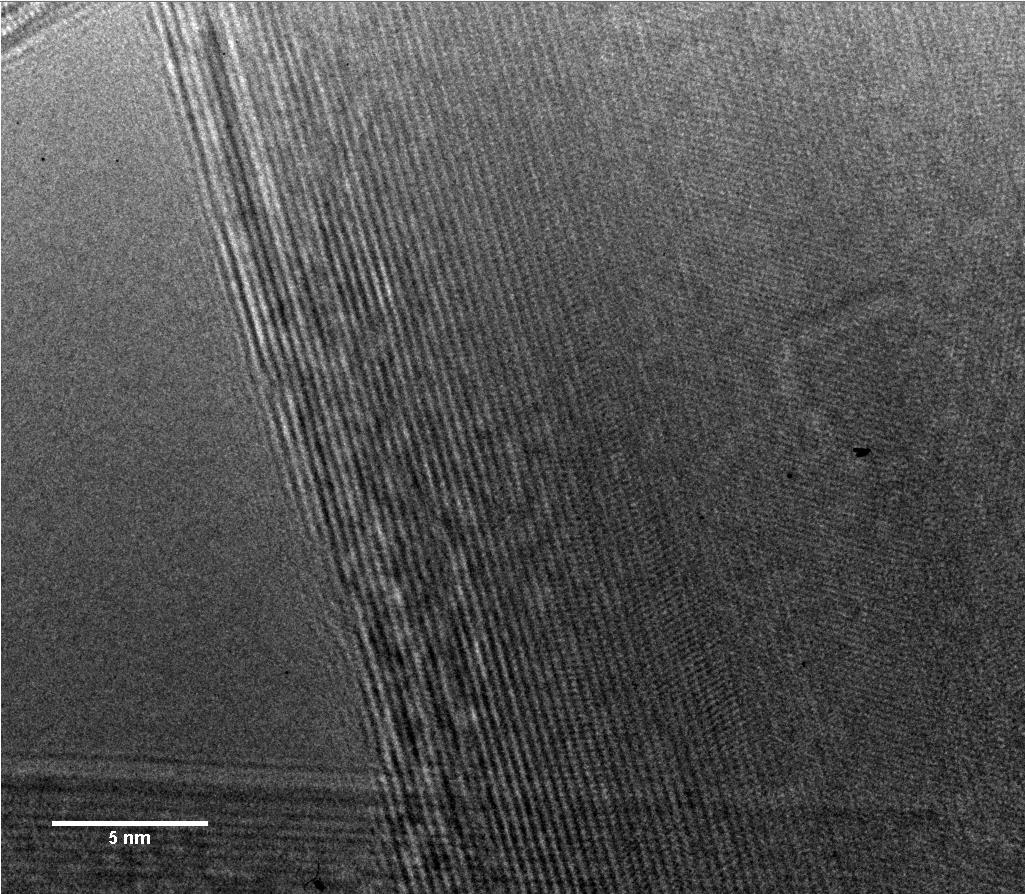

Single layer sheets of graphene have been synthesised at the company's industrial processing facilities in the UK, as well as bilayer and low multi-layer amalgamations. Now the company plans to focus on differentiating and separating the single atom width sheets.

Graphene is super strong, lightweight and highly conductive, exhibiting metallic-like properties in 2D form. It could revolutionise a host of future applications across a wide range of sectors such as light materials (aerospace and automotive), semiconductors, energy electrodes, nanotechnology and printable inks.

While graphene is traditionally known to incur high costs of production, Metalysis says that it is able to produce the largely industrially inaccessible material at no additional production cost to its conventional operations. The company is now focused on further process optimization and plans to pursue commercial opportunities during the coming year.

Lucrative markets ‘We are pleased to announce another exciting achievement on behalf of our technical team,’ said Dr Dion Vaughan, CEO of Metalysis. ‘Our proven technology can synthesise graphene monolayers with no operational or production cost impacts on our core metal powder business. ‘Producing graphene could enable Metalysis to add new, lucrative markets to those it is already serving; markets in which our arrival could be highly disruptive when global product demand is considered against the sheer amount of graphene we could produce in conjunction with our Gen 4, and later Gen 5 modular expansions. Gen 5, by way of illustration, envisages scaling up production capability for highly profitable niche multi-metal powders to thousands of tonnes per annum.’

This story is reprinted from material from Metalysis, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.