UK-based additive manufacturing (AM) specialist Metalysis has formed a new partnership with K Home International, an engineering and design consultancy specialising in the primary metals industry, particularly aluminum smelting. According to the companies, the new partnership will help scale up Metalysis’ process for producing titanium powder. It will also progress the commercial application of the technology, by expanding its capacity, lowering production costs and increasing efficiency. The companies also plan to improve the design, building and operation of the commercial production facilities.

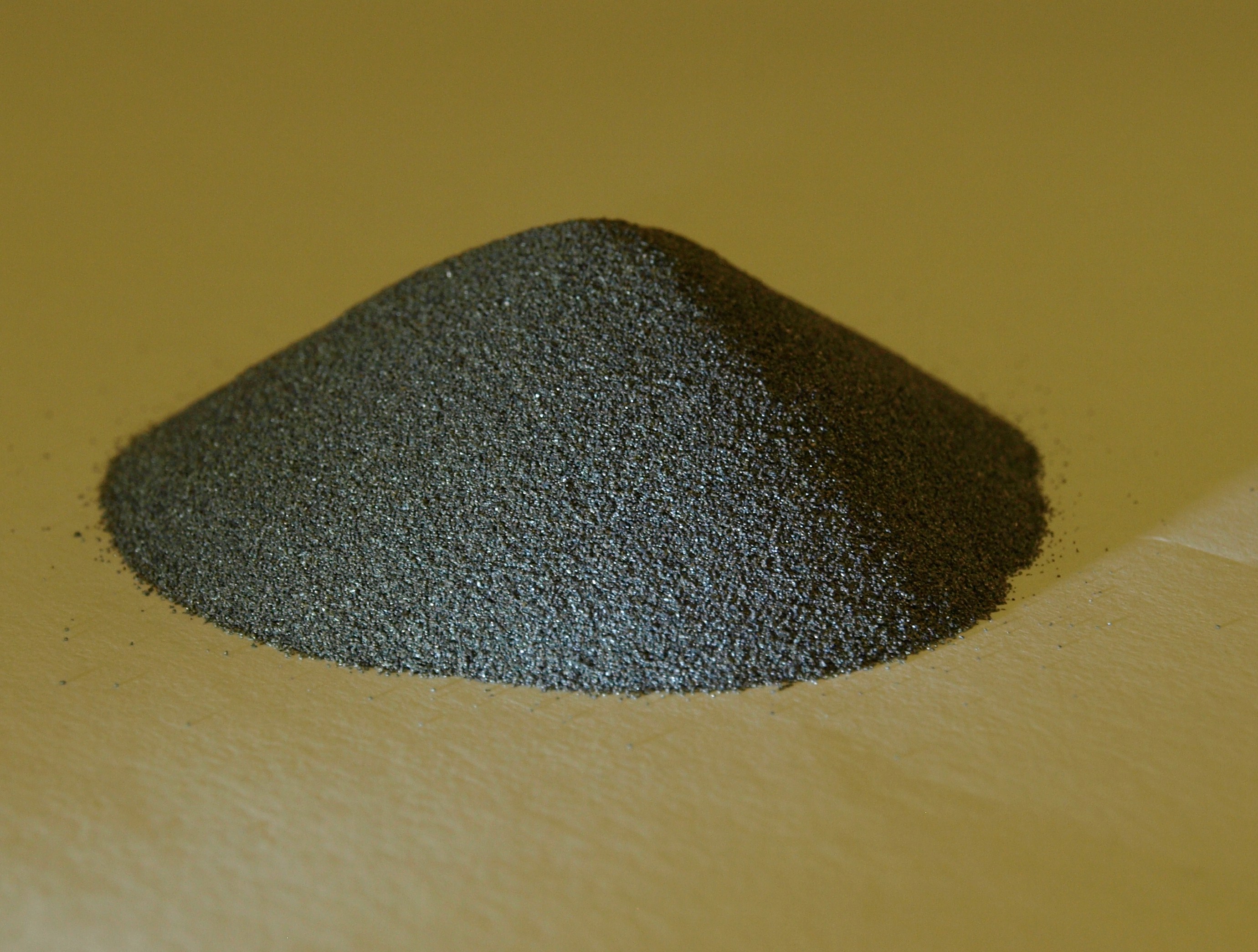

Metalysis’ technology transforms ores directly into metal powders using electrolysis in a single step. This technique can be used to lower the cost of producing high value metal powders such as titanium and tantalum, which can be used in a variety of new applications to satisfy the growing demand for low cost, light weight, high strength and corrosion resistant metals, particularly for AM.

‘This partnership represents a very exciting opportunity to bring together such immense, complementary expertise to expand and strengthen our production capacity,’ said Dion Vaughan, CEO of Metalysis. ‘This combined experience, underpinned by a recent injection of investment, represents a powerful platform for growth, which will enable us to deliver greater volumes of product for our customers and support further innovation in new sectors going forward.’

This story uses material from Metalysis, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.