According to the company, 3D metal printing can be expensive because titanium powders currently sell for US$200-US$400 per kilogramme. However, Metalysis’ process of producing low-cost titanium powder could lead to a greater use of titanium in components across the automotive, aerospace and defence industries.

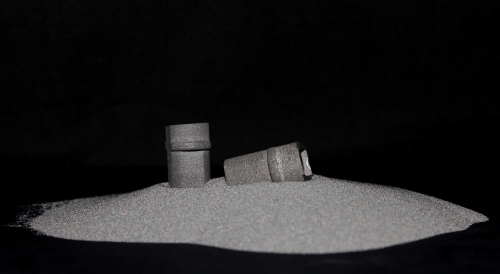

The powder is being used at Sheffield University’s Mercury Centre, using Renishaw’s 3D printer to make the parts.

Metalysis creates titanium from rutile sand, a naturally occurring titanium ore present in beach sands, in one single step. The process is radically cheaper and environmentally benign compared with existing titanium production methods, such as the energy-intensive Kroll process. Currently, the manufacture of titanium powder involves taking the metal sponge produced by the Kroll process, which is then processed into ingot billets, melted into bar form and finally atomised into powder – a costly and labour-intensive four-step process. Metalysis takes rutile and transforms it directly into powdered titanium using electrolysis. The low-cost titanium powder can be used in a variety of new applications whereas previously the metal has been excessively expensive for use in mass production of lower value items.

In addition to titanium, Metalysis is developing tantalum powder and can use its technology to produce a wide range of specialist metals (including rare earths). Furthermore, innovative alloys can be produced using Metalysis’ technology because the process is conducted in the solid state, so that metals with significantly different densities or melting points can be alloyed. Metal powders created by the Metalysis process can be engineered to get particle size and distribution correct for a range of PM applications.

“The Metalysis process could reduce the price of titanium by as much as 75%, making titanium almost as cheap as specialty steels,” said Dion Vaughan, CEO of Metalysis. “We believe that titanium made by the Metalysis process could replace the current use of aluminium and steel in many products. This world-first for a titanium 3D printed component brings us a step closer to making this a reality.”