Morgan Advanced Materials has worked with a Norwegian flat rolled aluminum supplier to improve its health and safety.

Morgan’s thermal ceramics business has worked with Hydro Aluminum for more than two decades, supplying a range of refractory ceramic fiber (RCF) caster tips for the company’s continuous aluminum casting process.

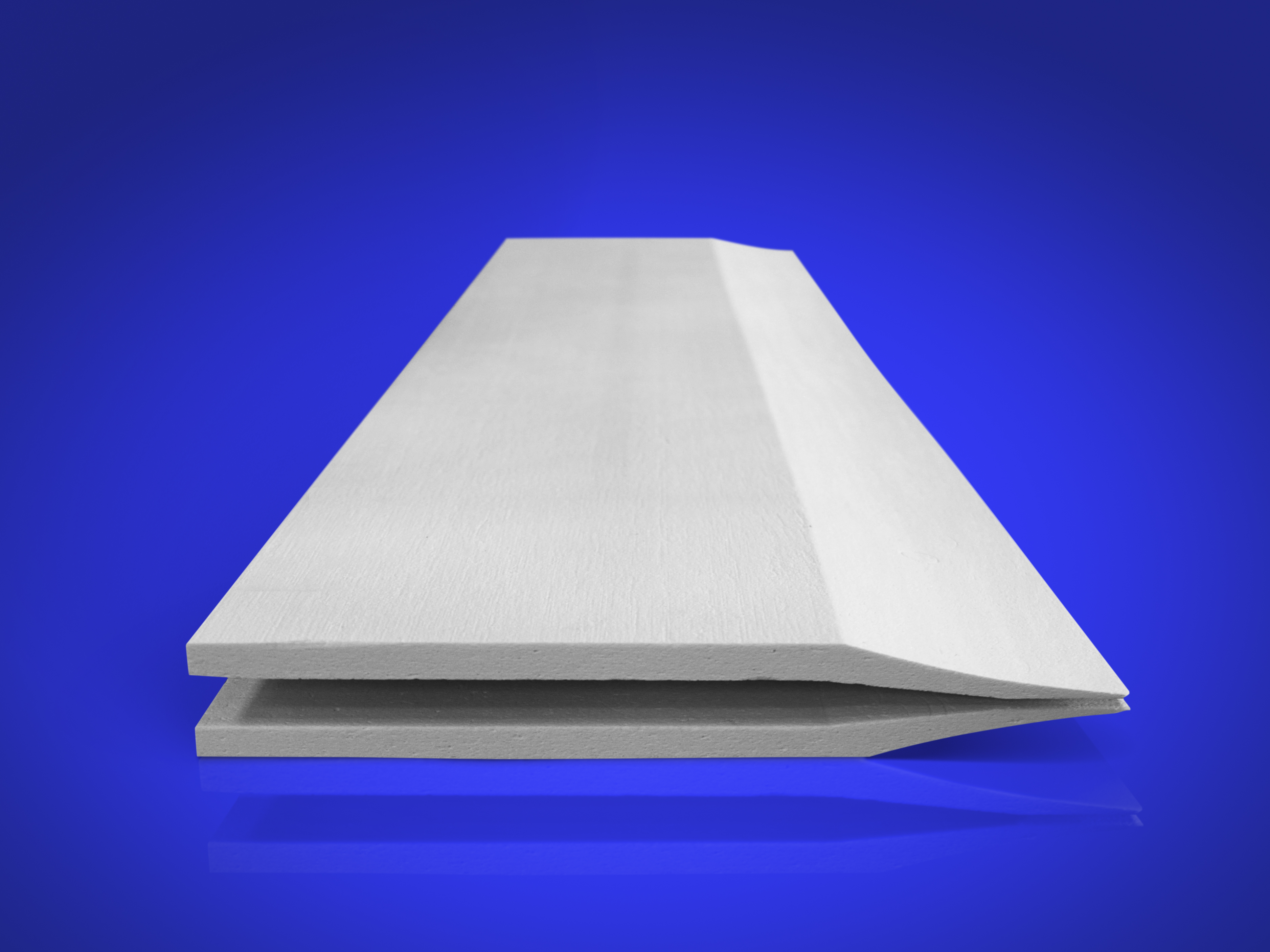

The most recent project has seen Morgan support Hydro Aluminium in its drive to move away from RCF caster tips to help improve onsite health and safety. Caster tips play a key role in feeding the aluminum into large steel rollers which roll the material to the required thickness.

The Hydro team consulted Morgan about the possibility of manufacturing caster tips in other materials. They wanted something which would deliver the same thermal expansion, hardness and density specification as the previous RCF-based products, while also leaving a very clean, dust- and mark-free surface after machining.

Close collaboration

Most importantly, any alternative material needed to be exonerated from carcinogen classification under Nota Q of European Directive 67/548. This would ensure that REACH authorisation will not be a problem, a concern arising following the inclusion of refractory ceramic fibers on the SVHC list in 2009 and its subsequent recommendation for authorisation in 2013.

Working in close collaboration with their counterparts at Hydro Aluminium, Morgan developed a range of bespoke caster tips made from its low biopersistent Superwool fiber range. Morgan created a special formulation of Superwool fiber for this application and even modified its production process to eliminate the possibility of the ‘shot’ within the fiber creating marks on the aluminum being processed.

This story is reprinted from material from Morgan Advanced Materials, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.