Anodes, which are crucial to the transformation of alumina into aluminum, are generally fired in graphite, in anode baking furnaces that incorporate insulation bricks. However, historically these bricks have been subject to damage and compromise as a result of the baking process, and a better quality alternative has long been sought.

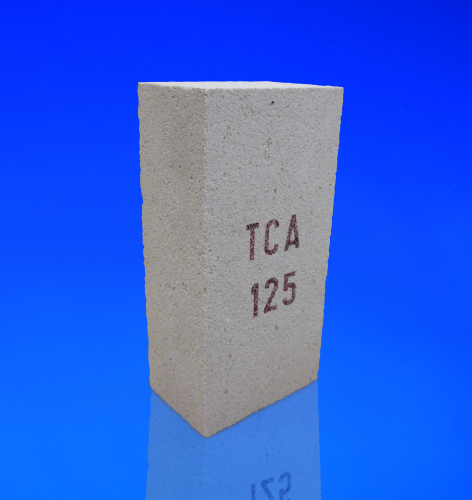

The TCA 125 has a cold crush strength of at least 8.0 MPa and permanent linear change (PLC) below 1% at 1350°C after 12 hours of firing. Previously, bricks of this quality had to be produced on hydraulic presses, however, extended development and experimentation by Morgan has resulted in the formulation of a new composition that allows such bricks to be produced using the ‘Slinger’ process, yet still achieve all of the properties required, in compliance with ASTM norms.

Various sizes

The ‘Slinger’ process is a form of low-pressure extrusion of a wet clay mix containing high levels of burnout additives, with the additional processing step that the semi-extruded material gets ‘slung’ onto a continuous belt to generate additional porosity, before drying and firing.

Morgan can now produce TCA 125 bricks in various sizes up to a maximum 640×250×76 mm (25 x 10 x 3 inch), including the standard 3-inch (76mm), Italian, German and French brick sizes. The company can also supply a wide range of high temperature insulation bricks and monolithics, as well as fire protection materials suitable for many applications and industries.