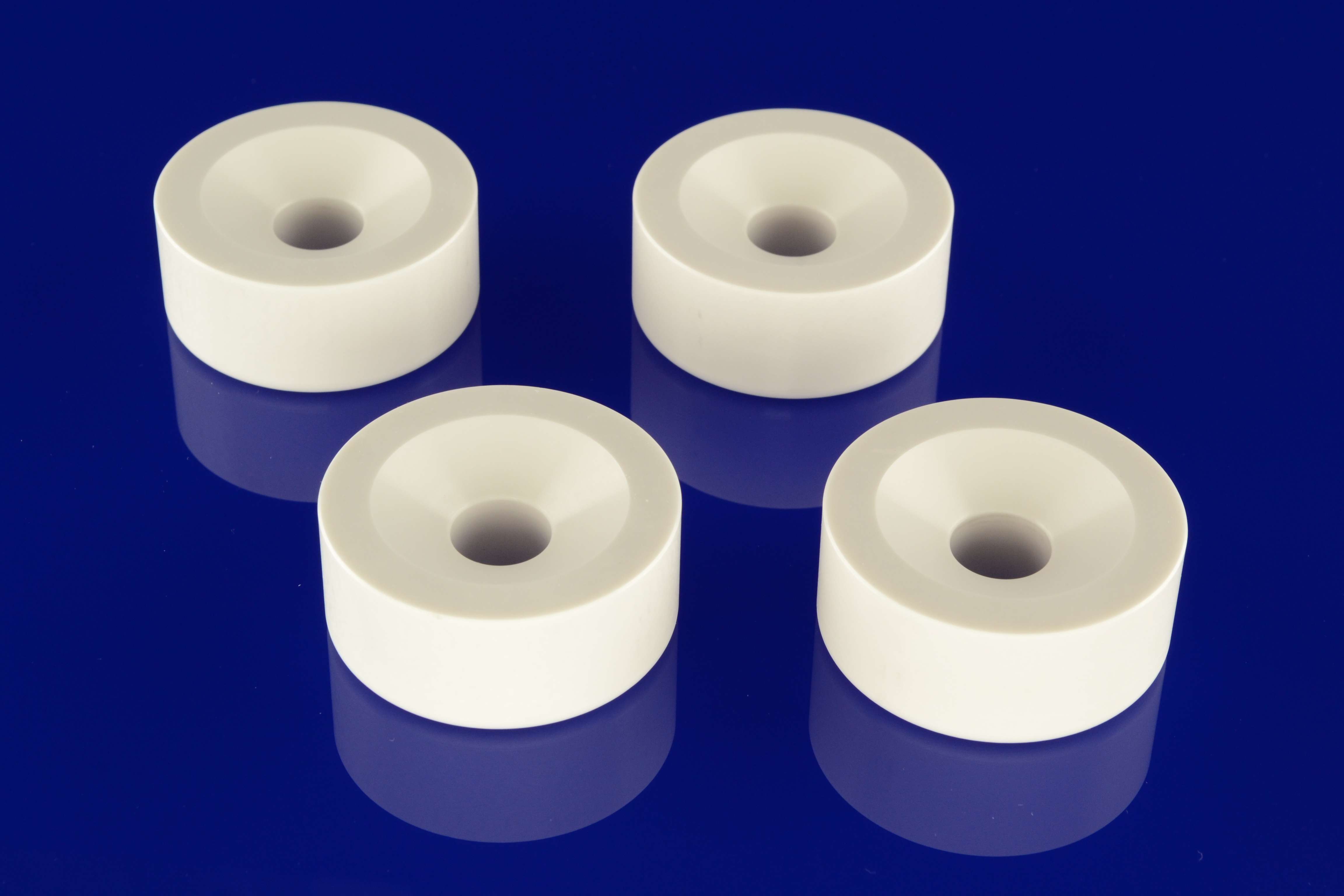

Morgan Advanced Materials has developed Nilcra Zirconia TS Grade, a high performance, hot extrusion die, made using ceramic materials specially designed for use within copper and brass extrusion. The die offers a more efficient alternative to conventional metal-based dies, and is available as an insert only, or as a ready-to-use assembly shrink fitted within a steel retainer, the company says.

Nilcra Zirconia TS Grade has been proven by Morgan to provide up to a 30 times lifetime increase when compared to alternative metal dies, which typically only last for 5-10 pushes. The ceramic die is reportedly not susceptible to creep at elevated temperatures enabling product size to be maintained throughout the life of the die.

Morgan’s Research and Development team developed the Nilcra Zirconia TS grade solution as an alternative die material with low thermal conductivity, enabling reduced heat transfer from the extruded product to the die body and holder. The material also has improved hardness and wear resistance properties that maintain a high level of surface finish on extruded product.

‘We wanted to develop a material that not only helps our customer to eliminate production downtime associated with poor die life, but also reduces their overall process costs by providing superior product quality with reduced scrap rates,’ said Tim Hazlehurst, senior sales engineer.

This story is reprinted from material from Morgan, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.