Biofabrication is an emerging, multidisciplinary research field encompassing technological advances in 3D printing technology, combined with strategies in tissue engineering and regenerative medicine. Ultimately, biofabrication research aims at enabling the on-demand fabrication of human tissue and organ substitutes for drug screening, disease modelling and transplantation. In a new article published in Biomaterials, researchers from Trinity College Dublin use state-of-the-art 3D bioprinting to create functional osteochondral tissues targeting the treatment of articular cartilage loss or damage as a result of osteoarthritis [Daly & Kelly. Biomaterials (2019) doi: 10.1016/j.biomaterials.2018.12.028].

Authors Daly and Kelly highlight that osteoarthritis is the most common joint disease and leading cause of disability, affecting millions around the world. As an alternative to joint replacement, tissue engineering strategies are being developed to reproduce native cartilage tissues and facilitate tissue healing. However, challenges in replicating the complex collagen fibre structure of articular cartilage have limited the biomechanical functionality of tissue substitutes.

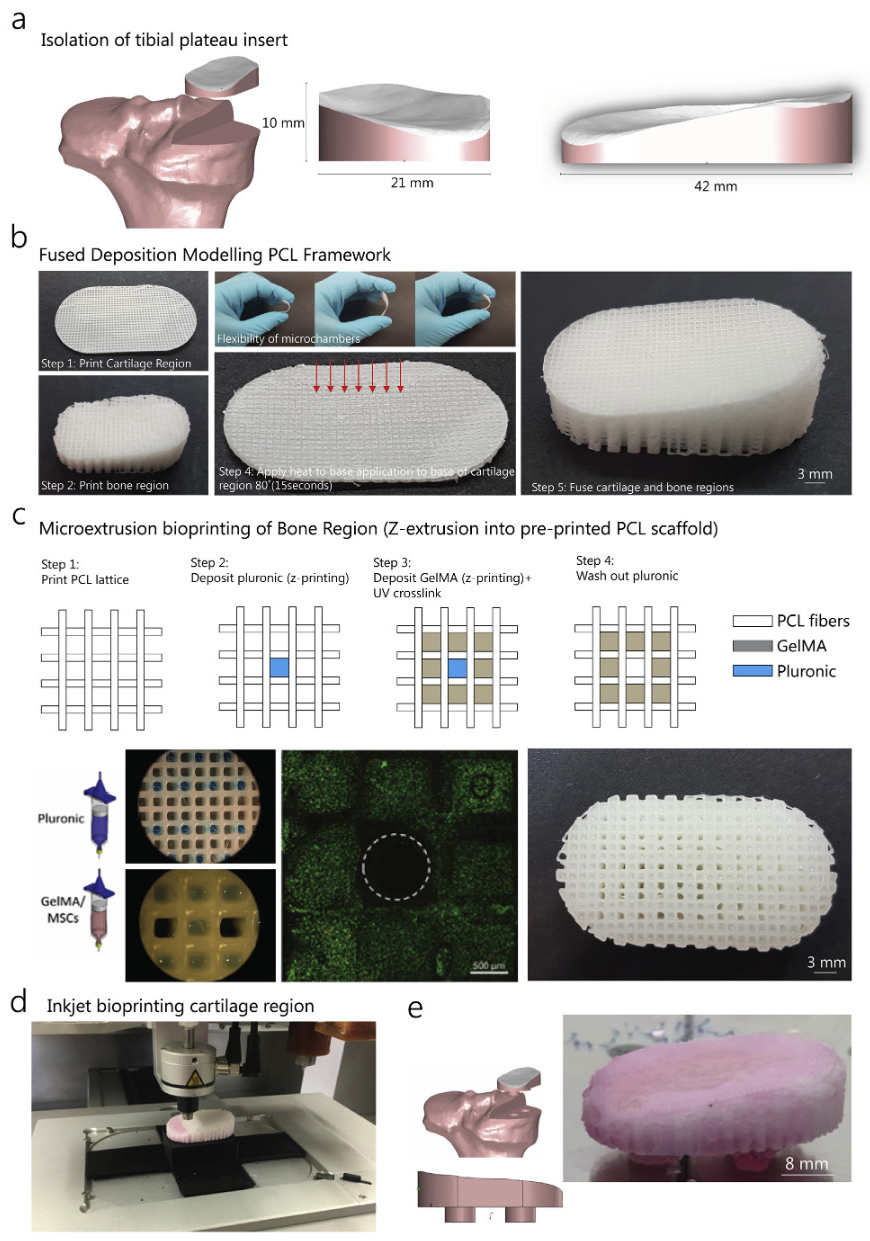

Daly and Kelly propose a biofabrication approach to create highly-organised engineered osteochondral tissue by inkjet-printing mesenchymal stromal cell (MSCs) and chondrocytes into 3D printed PCL scaffolds. Through localised deposition of MSCs into the scaffold microchambers using a 3D Discovery bioprinter (RegenHU, Switzerland), cell spheroids are successfully formed and are shown to aggregate, proliferate and eventually fuse over the ‘walls’ of the scaffold wells following in vitro culture. Overall, biologically-relevant tibial plateau inserts are fabricated suitable for regenerating tissue and the bone-cartilage interface within joints.

The authors also investigate the efficacy of static versus dynamic culture over a 10 week period, assessing the quantity and orientation of key extracellular matrix (ECM) proteins. Using dynamic culture, enhanced articular cartilage and bone formation favourable for osteochondral applications is achieved.

In this study, the use of 3D bioprinting enabled the rapid fabrication of anatomically-relevant osteochondral tissue substitutes using multiple print heads to precisely control the deposition of MSC/chondrocyte co-culture cells, MSC-laden hydrogel and support material into pre-printed PCL scaffold. Novel biofabrication strategies such as these are harnessing innovations in 3D printing to enable the fabrication of complex tissue substitutes and develop innovative solutions to healthcare challenges.