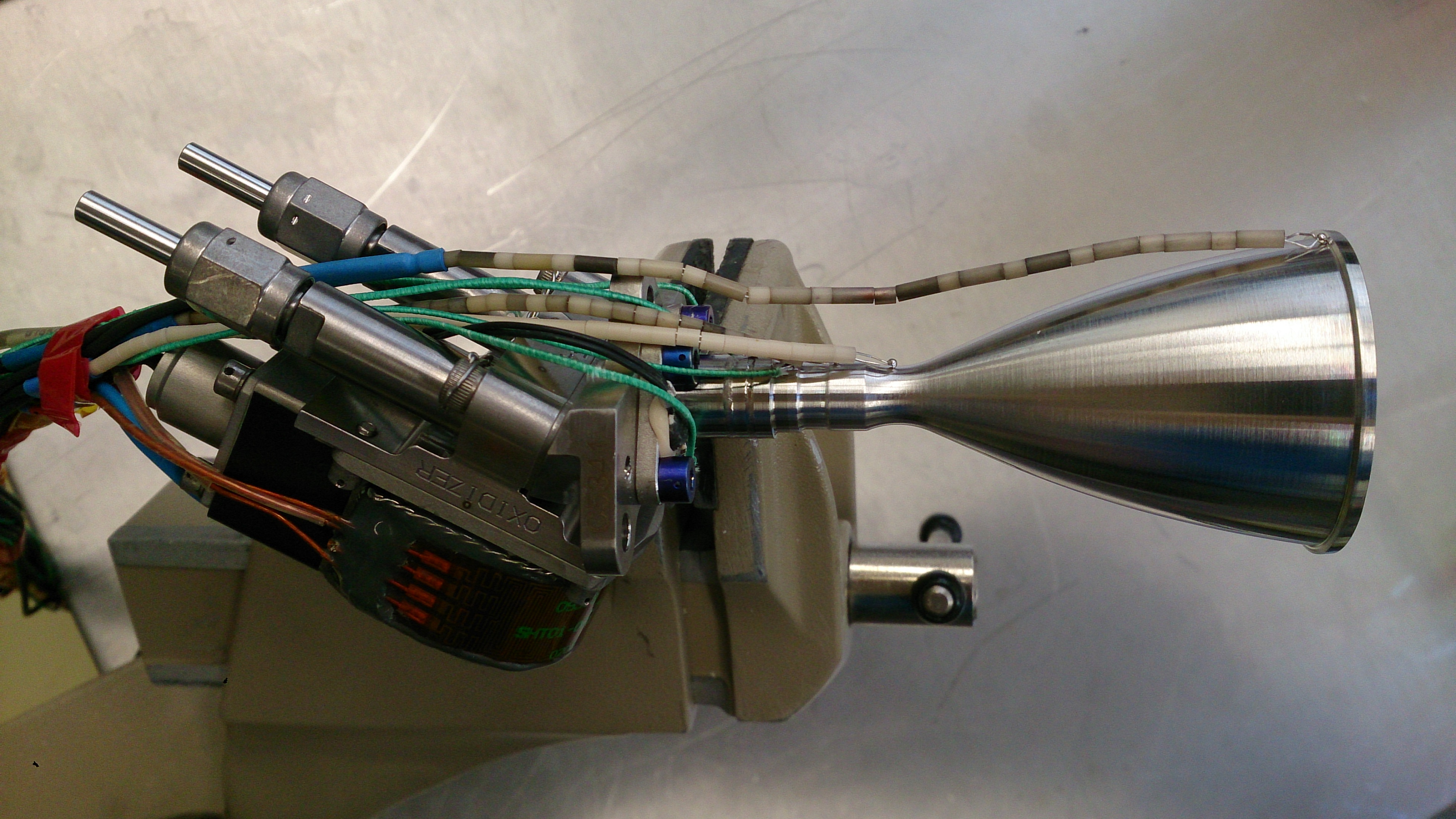

A spacecraft thruster tested by Airbus and the European Space Agency (ESA), featuring a platinum combustion chamber and nozzle made by 3D printing, has successfully withstood a series of firings lasting more than an hour and 618 ignitions.

The firings included a single burn of 32 minutes, during which a maximum throat temperature of 1253°C was attained.

‘This is a world first,’ said Steffen Beyer of Airbus Defence & Space, which managed the project. ‘‘It demonstrates that performance comparable to a conventional thruster can be obtained through 3D printing.’

The combustion chamber for the 10 N hydrazine thruster was printed in platinum/rhodium alloy using a laser beam applied to a metal powder bed. Engineers used a laser machine normally employed for making jewellery to produce the part.

‘The aim was to test this alternative manufacturing method as a way of reducing material costs,’ said Laurent Pambaguian, overseeing the project for ESA. ‘At the start we were by no means certain it could be done, or even whether the metal powder could be prepared to the appropriate quality.

‘Considering that platinum currently costs €40 a gram, 3D printing offers considerable future savings,’ added Dr Beyer.

‘We produce 150–200 thrusters in this class per year for different customers. 3D printing should allow shorter production cycles and a more flexible production flow, such as manufacturing on demand.’

Printing process

The prototype thruster was produced and tested at the Airbus Defence & Space facility in Lampoldshausen, Germany, through an ESA project called Additive Manufacturing Technologies for Advanced Satellite Thrust Chamber (AMTAC).

The platinum/rhodium was supplied by Germany’s Heraeus company, then atomised by Nanoval with the additive manufacturing (AM) process overseen by Germany’s Fraunhofer Institutes of Laser Technology, in Aachen, and Machine Tools and Forming Technology, in Augsburg.

‘Platinum/rhodium was chosen for this first phase as the most mature platinum alloy for additive manufacturing,’ said Dr Beyer.

‘In the next phase, we will attempt to print using a new alloy, platinum/iridium, which has performance advantages. This alloy cannot easily be manufactured by traditional techniques like casting and forging, so printing is the only way it can be harnessed for space use.’

Exceptional potential

The project is part of ESA’s long-running Advanced Research in Telecommunications Systems programme, ARTES.

‘This successful test is a major step towards the goal of full product qualification under ARTES,’ said Clive Edwards, ESA telecom platform engineer.

‘Thrusters made using this technology have exceptional potential for the satellite reaction control thruster market, offering class-leading performance at competitive prices.’

‘This latest success opens the way to further developments,’ added Tommaso Ghidini, head of ESA’s materials technology section. ‘We aim to move to other materials, including Inconel and copper, for larger volumes, progressing to kilonewton-scale thrusters for both spacecraft and launchers.’

‘Our to-do list ‘roadmap’, prepared with the active participation of industry and the Member States, summarises and coordinates the work European industry needs to perform to routinely employ 3D-printed parts for space, including all necessary qualification and verification processes.’

‘The potential of 3D printing makes it an important element of our new advanced manufacturing initiative, which focuses on a range of technologies to slash European manufacturing costs and lead times while improving performance and boosting competitiveness,’ added Mikko Nikulainen, head of ESA’s component technology and space materials division.

This story is reprinted from material from ESA, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.