Ireland-based Croom Precision Medical, which makes medical implants, has worked with 3D printing company Renishaw to make more complex parts using additive manufacturing (AM).

Previously, in order to assess the chemical, mechanical and morphological quality of parts, CPM carried out a series of offline tests. Whilst these tests are essential to measure mechanical and chemical consistency of the implants, they can be time consuming and add to the overall cost per part, Renishaw said. The companies planned to change Croom’s production process so that more of the monitoring can take place during the manufacturing process.

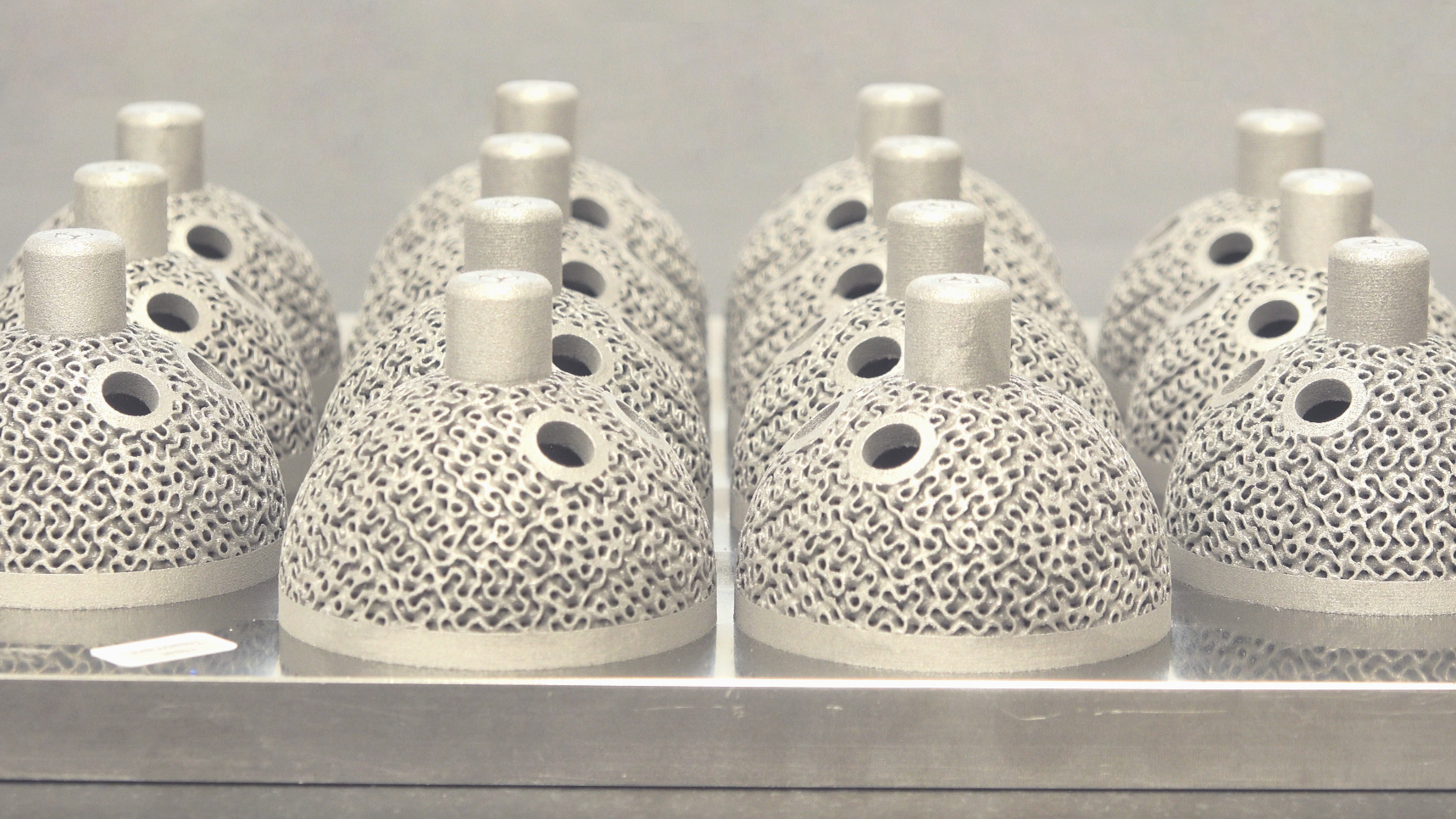

As well as this, Croom used a RenAM 500M 3D printer to make titanium gyroid lattices on acetabular (hip) cups, a design feature which would not have been economically feasible to produce using other methods, Renishaw said.

This story uses material from Renishaw, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.