Pacific Northwest National Laboratory (PNNL) has reportedly developed a way to produce nanostructured rods and tubes from aluminum alloy powder in a single step.

Using the solid phase processing method, researchers were able to eliminate any steps required during the conventional extrusion processing of aluminum alloy powders. The end products also had improved ductility of up to two or three times that found in conventional extruded parts, the lab says.

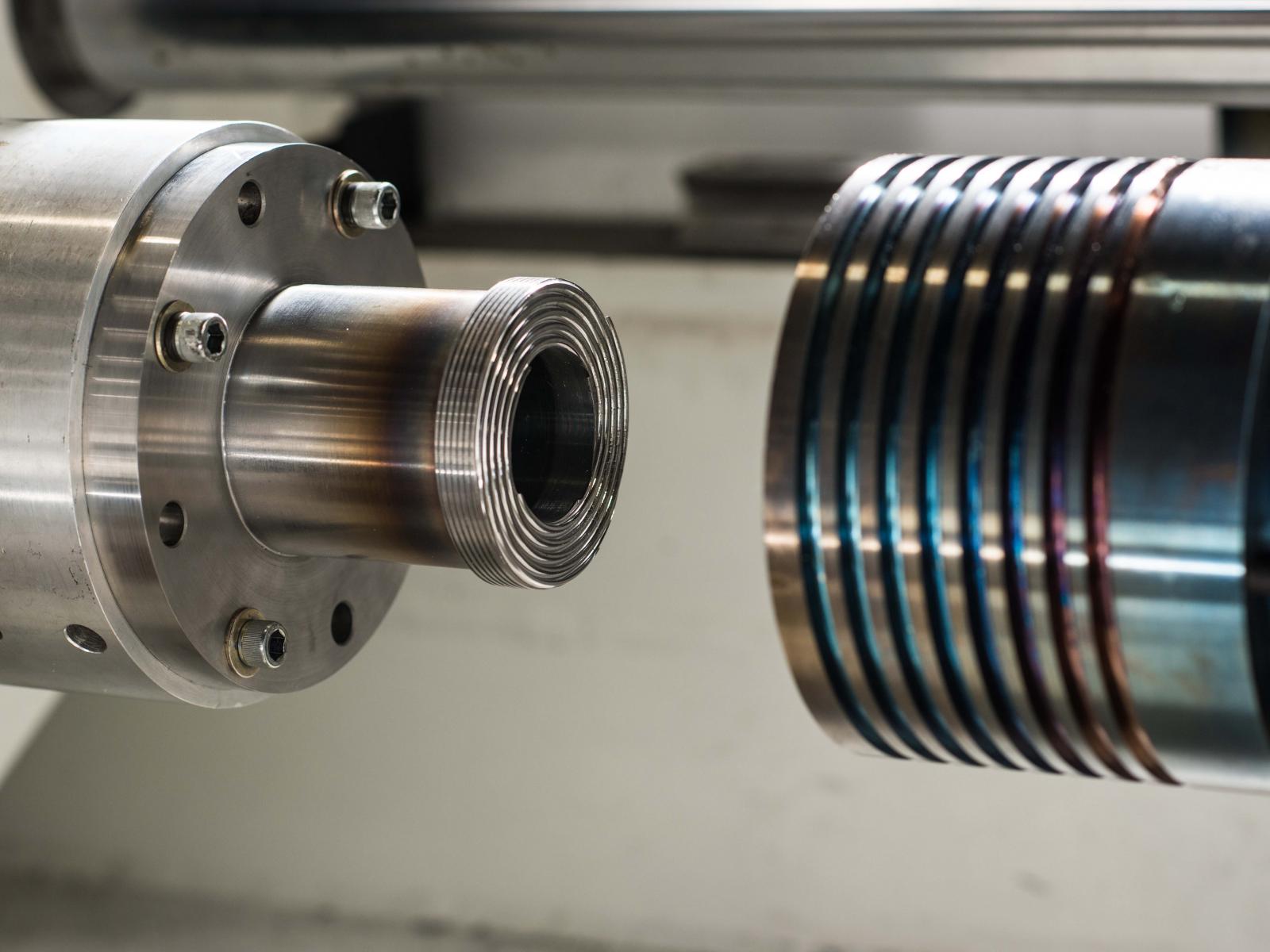

The team was able to extrude nanostructured aluminum rods directly from powder in a one step, using PNNL’s ShAPE shear assisted processing and extrusion technology. During the process an Al-12.4TM aluminum alloy powder provided by SCM Metal Products was poured into an open container. A rotating extrusion die is then forced into the powder, which generates heat at the interface between the powder and die. The material softens and extrudes, eliminating the need for canning, degassing, hot pressing, pre-heating, and decanning.

'This is the first published instance of an aluminum alloy powder being consolidated into nanostructured extrusions using a single-step process like ShAPE,' said PNNL materials scientist Scott Whalen, who led the study. 'The elimination of both the processing steps and the need for pre-heating could dramatically reduce production time as well as lower the cost and overall embedded energy within the product, which could be beneficial for automotive manufacturers who want to make passenger vehicles more affordable, lighter, and fuel-efficient for the consumer.'

This story uses material from PNNL, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.