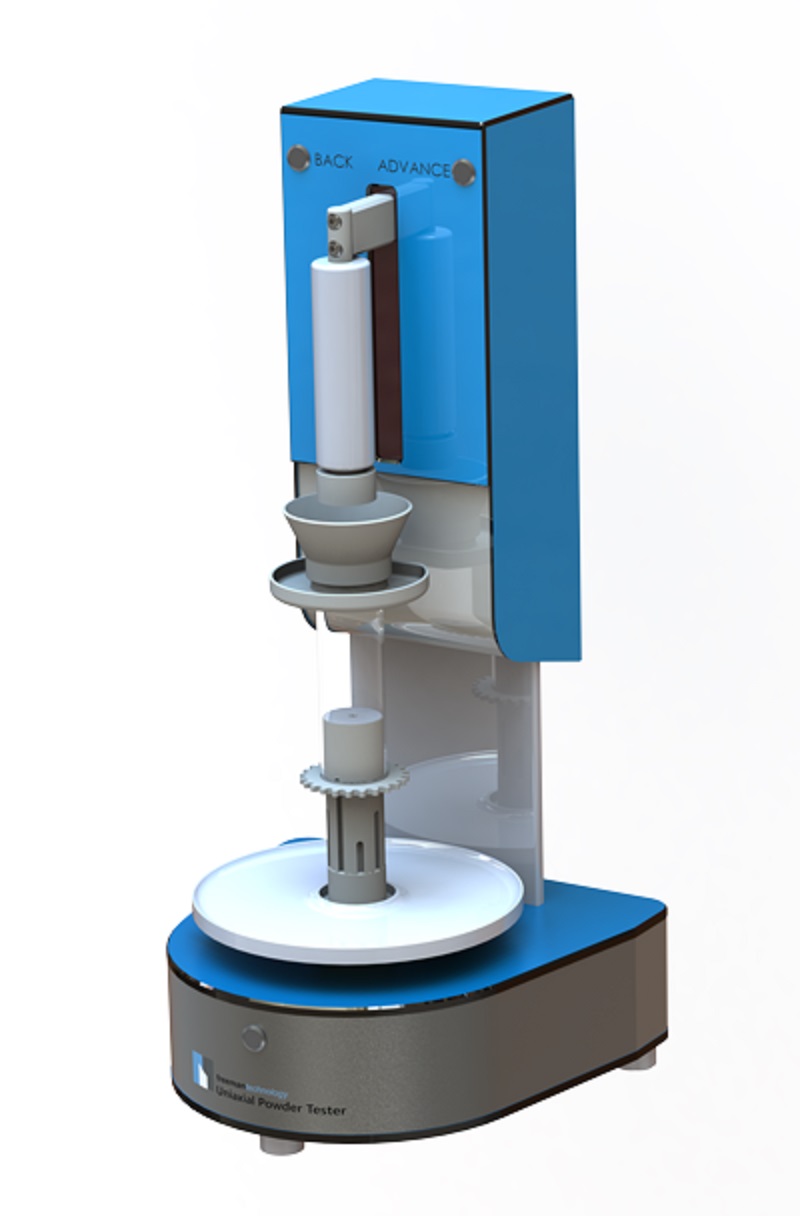

Freeman Technology has launched the Uniaxial Powder Tester (UPT) which it says is the world’s first stand-alone uniaxial tester for powder characterisation.

Developed in collaboration with the University of Edinburgh and a major industrial powder processor, the new tester delivers automated measurement, making it potentially more cost effective than traditional powder testing techniques.

‘Uniaxial powder testing is a simple and intuitive method that measures an intrinsic property of a bulk solid,’ said Tim Freeman, managing director of Freeman Technology. ‘The UPT draws on our in-depth understanding of powders.’

The new instrument measures unconfined yield strength (UYS), a parameter typically derived indirectly via biaxial shear cell analysis, which is used to assess and rank the flowability of powders. Uniaxial testing involves the construction of a consolidated powder column, which is then fractured through the application of a vertical stress to directly measure UYS, also known as σc. Fundamental to the successful implementation of the technique is the construction of a uniformly consolidated powder column, and subsequent removal of the containing sleeve with minimal disturbance of the compacted column.

This new tester has a number of innovative features that are crucial to ensure reproducible measurement for a wide range of powders, including a unique and novel system for the application of double-ended compression,’ added Freeman.

The new instrument is available in either a manual or an advanced version.

This story uses material from Freeman Technology, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.