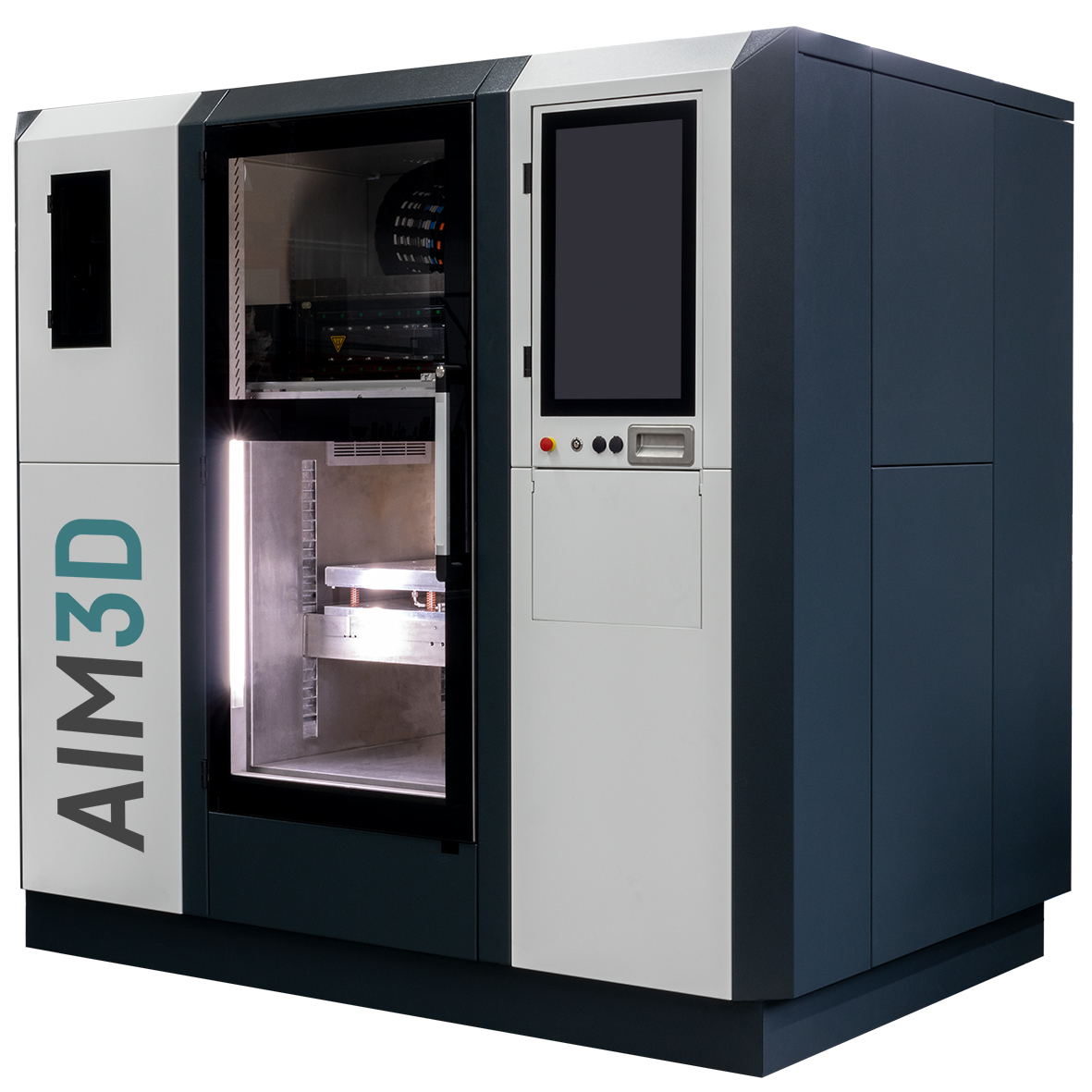

Multi-material additive manufacturing (AM) specialist AIM3D says that it has developed a new 3D printer for the composite extrusion modelling (CEM) process.

According to the company, the new ExAM 510 has a larger (510 x 510 x 400 mm) build area, higher precision and build rates of up to 250 cm³/h. It can print up to three different materials in parallel, including polyether ether ketone (PEEK), polyethylenimine (PEI), polysulfone (PSU) and polyphenylene sulfide (PPS), with and without fiber filling.

‘We are now offering a faster, bigger, hotter and more precise CEM process technology for additive manufacturing,’ said Clemens Lieberwirth, CTO at AIM3D.

This story uses material from AIM3D, with editorial changes made by Materials Today.