Cutting tool and tooling system specialist Sandvik Coromant has introduced two new ceramic insert grades that can performing high-speed, high-security turning operations on components made from heat resistant super alloy (HRSA) materials.

There is growing demand for aerospace engine parts that can withstand extreme temperatures beyond the capability of those made from Inconel and other high-performance super alloys, Sandvik says. ‘Although these powder metallurgic materials can be tailored to handle substantially higher temperatures, they are more difficult to machine than common HRSAs,’ the company added in a press release.

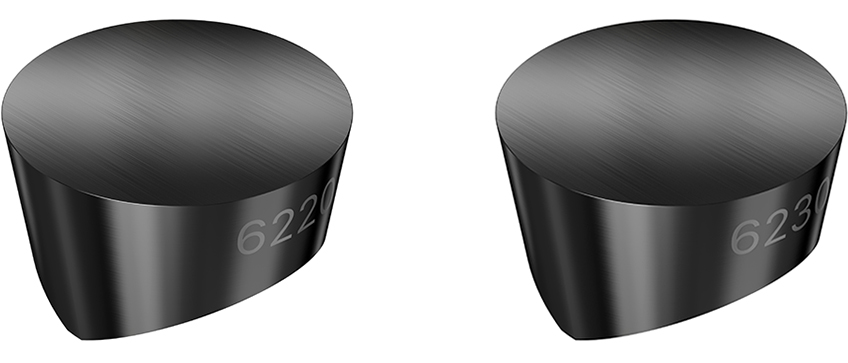

One common applications could be the turning of turbine discs. In a customer example machining a low-pressure turbine (LPT) disc made from Rene material (42-45 HRc) as part of the intermediate stage machining process, a CC6220 RPGX insert was deployed to perform pocketing and CC6230 RPGX inserts for rough-turning operation at cutting speeds as high as 400 m/min (1380 sfm). The process achieved a metal removal rate (MRR) of 80 cm3/min (5 inch3/min).

This story is reprinted from material from Sandvik Coromant, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.