Kyocera says that tooling parts incorporating its ceramic bearings can be easily sterilized for use in food and pharma production. According the company, the components also comply with FDA safety standards.

Kyocera also reports that it is able to trace different ceramics for this type of application from a single source, ensuring reliable traceability of the materials.

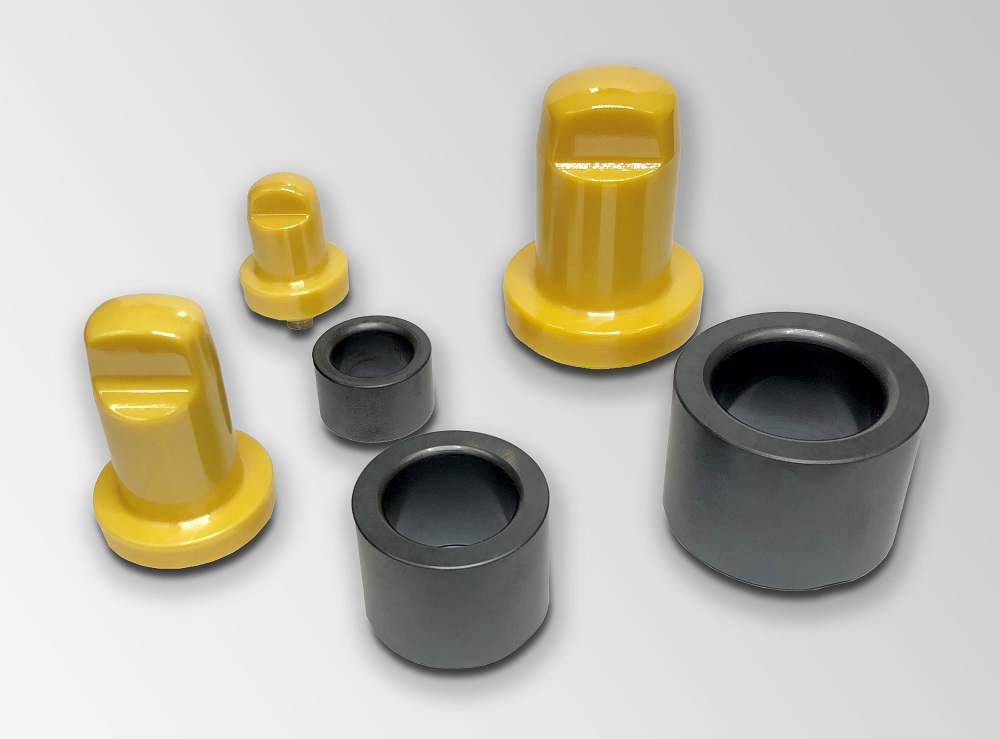

According to the company, parts such as magnetic mixers feature ceramic sliding bearings which are in direct contact with the mixed product, with the female bearing made from silicon carbide and the male from zirconium oxide. Both parts have to cope with frictional wear, temperature changes and corrosive attack by cleaning chemicals.

Kyocera says that its sliding bearings help ensure long lifetime and no particle shedding. Due to the sterility and inertia of the ceramics, the tanks stay clean, and ceramic bearings do not require additional lubrication. The resistance to temperature variations of both ceramics allows the use of cleaning and sterilization in place (CIP/SIP).

This story uses material from Kyocera, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.