Concept Laser says that it is 3D printing spare parts for beverage filling plants in Germany.

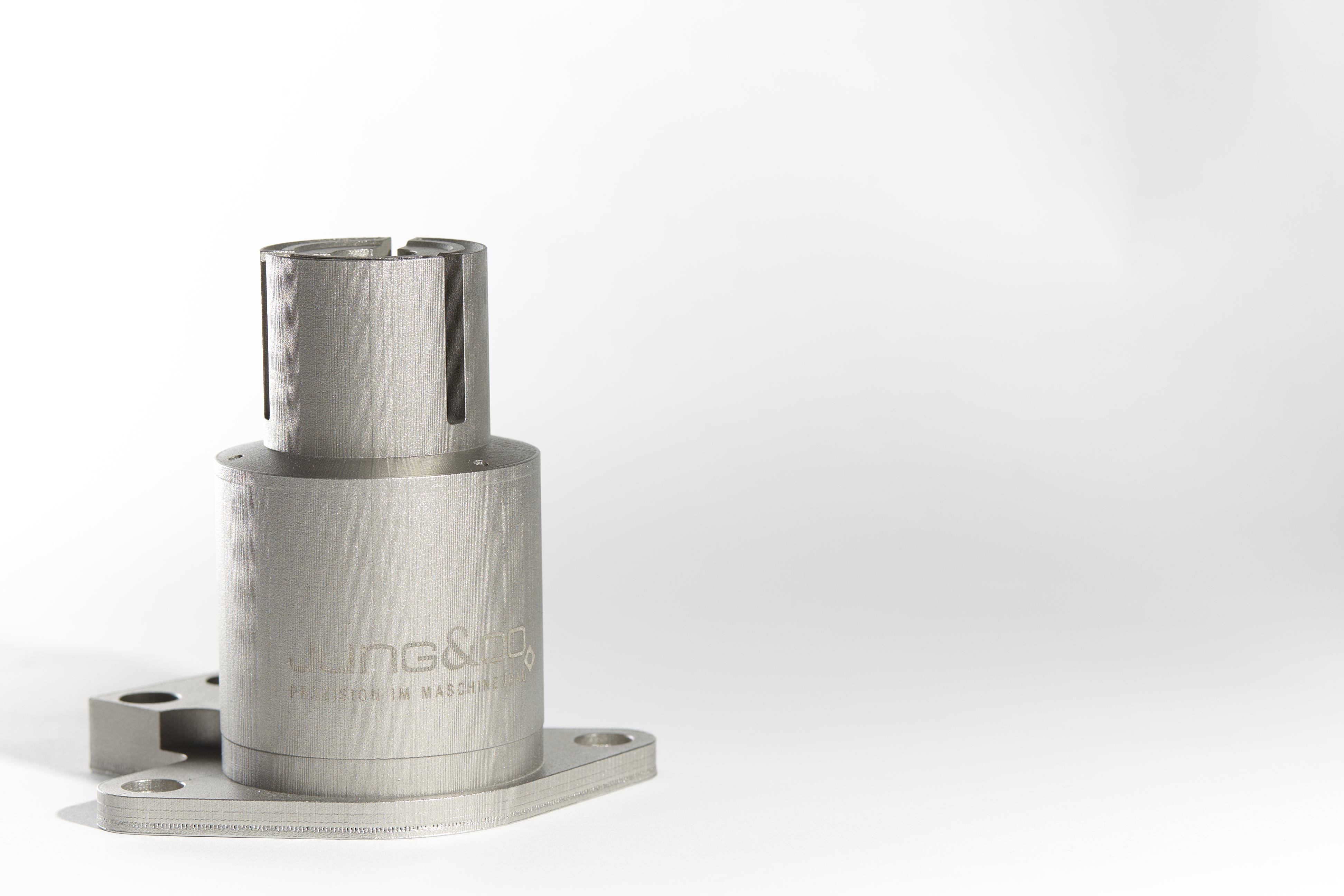

Jung & Co is a processor of stainless steel and caters for an array of sectors ranging from the food and beverage industry, pharmaceuticals and chemical engineering, plant engineering, aviation through to the fossil fuels extraction industry. One specialty is the production of spare parts made of stainless steel for beverage filling plants.

The company uses a M2 cusing Multilaser machine from Concept Laser to make the parts. The company can also make spare parts on demand using the additive manufacturing (AM) process, reducing downtime in the process.

This story is reprinted from material from Concept Laser, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.