Powder production technology developed at Ames Laboratory in the US has won a technology transfer award.

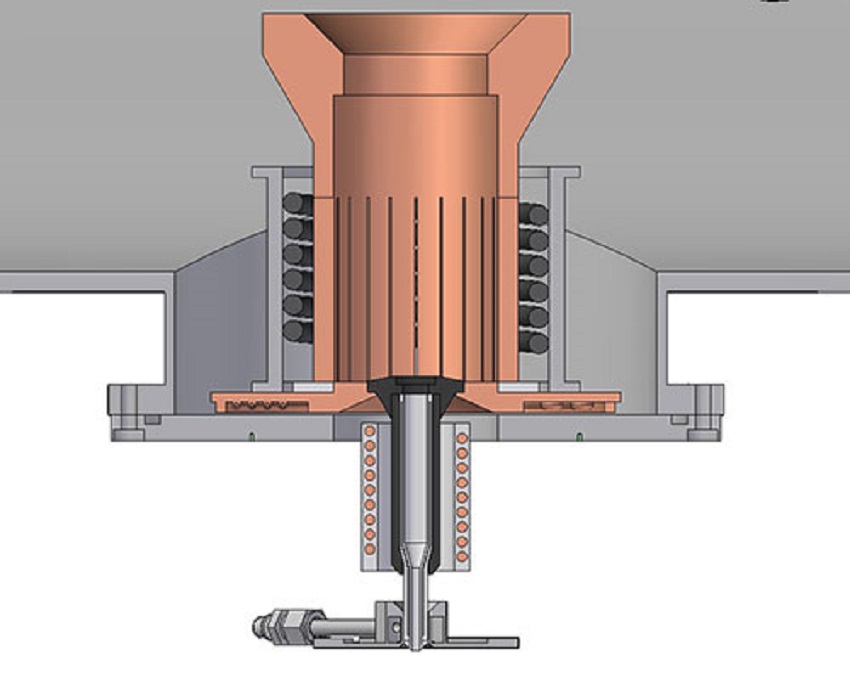

Senior metallurgist Iver Anderson and his team won the 2017 Excellence in Technology Transfer Award from the Federal Laboratory Consortium (FLC) Mid-Continent Region for the development of a pour tube that when adapted into a nozzle can produce titanium powder by a method that is said to be approximately 10 times more efficient than traditional powder-making methods.

The team suggest that this new method could lower the cost of high-quality, fine, spherical titanium powder to manufacturers by as much as 80%.

The award is shared by Andy Heidloff and Joel Reiken, formerly of Ames Laboratory and now of Praxair Surface Technologies Inc, and David Byrd, Ross Anderson and Emma White of Ames Laboratory. Praxair says that it has chosen to commercialize the titanium atomization technology from Ames.

‘Ames Laboratory is uniquely equipped and staffed with talented researchers who work as a team to develop breakthrough technologies in the production of atomized powders,’ said Dean Hackett, vice president of Praxair.

This story is reprinted from material from Ames, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.