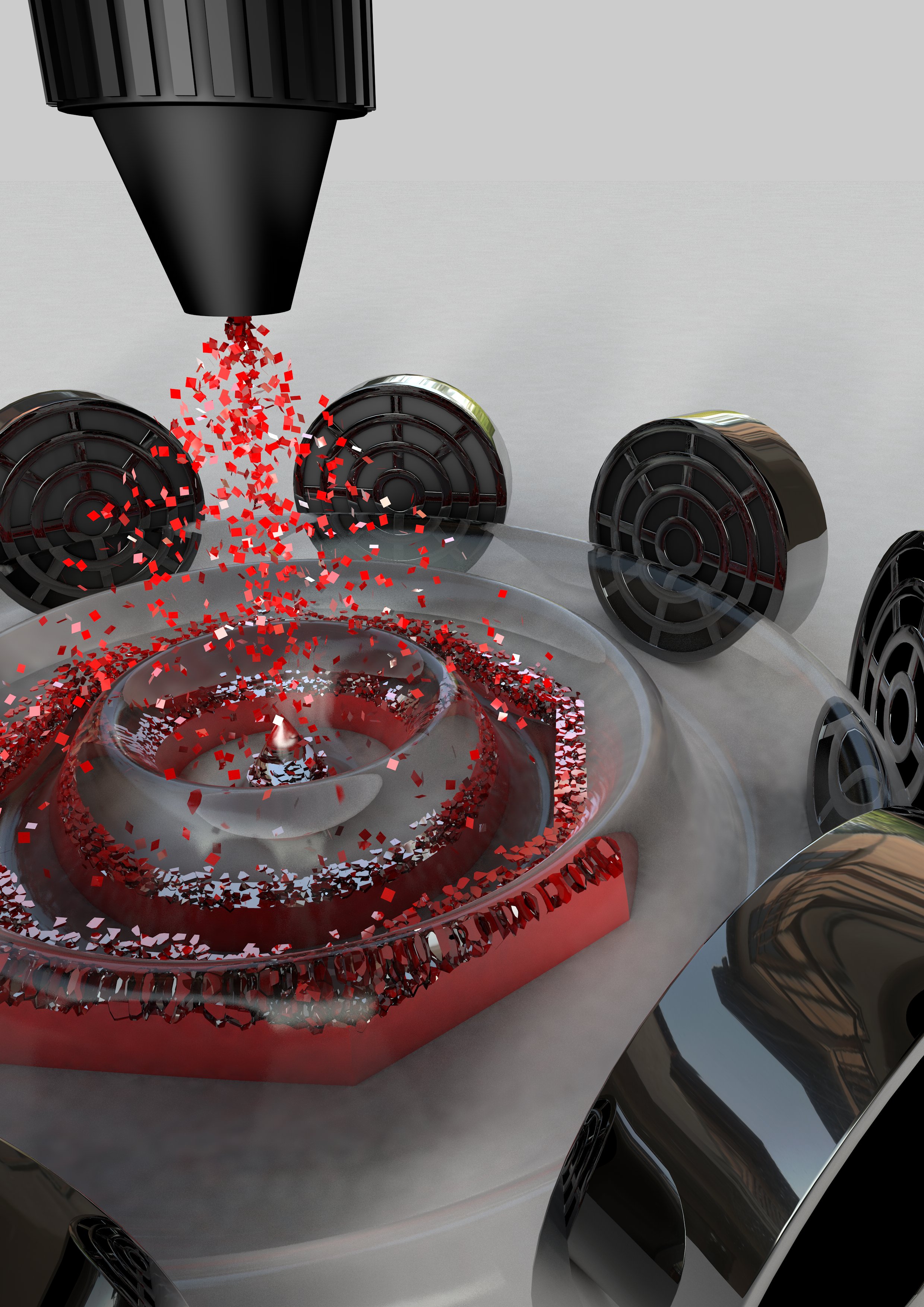

A new study by researchers at the universities of Bath and Bristol in the UK have demonstrated precise and predetermined patterns on surfaces from aerosol droplets or particles using a new computer-controlled ultrasound technique called 'sonolithography'. Being able to direct aerosol sprays with precision could lead to applications in drug delivery and wound healing, electronics, and printing by enhancing the speed, cost and accuracy of non-contact patterning techniques in air.

While ultrasound has previously been shown to levitate small particles, here the potential range of applications has been expanded through patterning clouds of material in air at scale and then algorithmically controlling how the material settles into different shapes. The study, published in Advanced Materials Technologies [Shapiro et al. Adv. Mater. Technol.(2021) DOI: 10.1002/admt.202000689], demonstrates the potential of sonolithography for biofabrication based on acoustic radiation forces coming from the interference of ultrasonic standing waves to direct airborne particle/droplet accumulation in specific areas.

The technique can rapidly pattern micrometer to millimeter scale materials onto many types of substrate over a macroscale surface area, and can be used for both indirect and direct cell patterning. This straightforward approach also offers much flexibility in both the substrate and deposited materials, such as aerosols, proteins and mammalian cells. As lead author Jenna Shapiro said, “Sonolithography enables gentle, non-contact and rapid patterning of cells and biomaterials on surfaces. Tissue engineering can use biofabrication methods to build defined structures of cells and materials. We are adding a new technique to the biofabrication toolbox.”

The approach was demonstrated in the 5–20 micrometer range, which can be a difficult scale for physical sorting mechanisms to be effective. While the ability of sound waves to manipulate particles is well known, the concept was extended to allow its wider availability to those without specialist acoustic knowledge, and the team have made the modular technique widely accessible to ensure it can be progressed for a range of uses.

Although they are just beginning to understand and explore the capabilities of the technique, it could find uses not only in biomedicine but for a range of materials, while in printed electronics sonolithography could work to arrange conductive inks into circuits and components, and in industrial processes where controlling microscale particles or droplets in an air stream is crucial, as in painting or spray coating.

The next step will be to introduce dynamic control to allow real-time manipulation of the acoustic field and the subsequent patterning, and in biofabrication and where sonolithography can help generate unique biomaterial microarchitectures. How these impact cell/material relationships, and the creation of mammalian tissues for modeling and regenerative medicine, will be of especial interest.