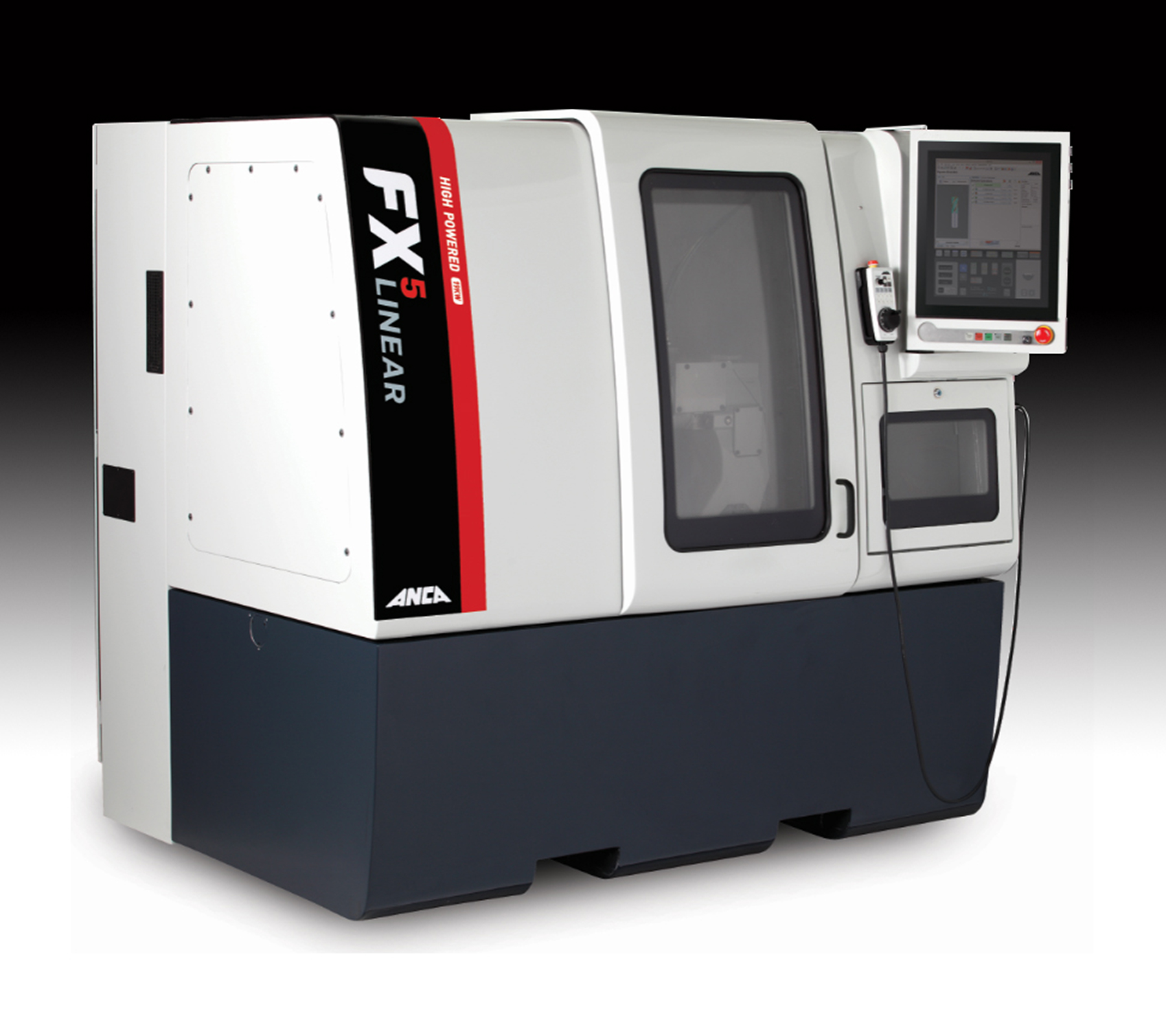

ANCA, which makes CNC grinding machines, says that it has upgraded its FX5 Linear two-wheel pack machine.

The machine how features a grinding spindle rated at 12kW peak power with an additional high-powered spindle option of 19kW. According to the company, limiting the spindle load to between 30% and 40% for fluting operations is common in order to maximize material removal rate. If the spindle load is likely to exceed 40%, tool manufacturers tend to allow for a second fluting pass to help extend wheel life and reduce wheel load. ANCA has conducted a spindle load analysis of fluting operations, identifying how many passes are recommended in relation to spindle load, comparing two flute endmills ground with either 6, 8, 10 or 12mm diameters. According to the company, its FX5 with new 9.5kW to a 12kW spindle can comfortably grind tools up to 10mm diameter in a single pass. A 12mm tool required a second grinding pass to keep the spindle load at 40%, rather than increasing to 60%, and with a 19 kW spindle, a 12mm endmill can grind a 40% spindle load in one pass, with an overall time saving of one minute and four seconds.

This story uses material from ANCA, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.