By Kari Williamson

The nano-polycrystalline diamond developed by Sumitomo Electric has a single-phase nano-polycrystalline body synthesised by the strong and direct bonding of fine diamond grains of several tens of nanometers.

It is a synthetic diamond produced by a special technique under higher temperature and pressure conditions than those used for producing conventional synthetic single-crystal diamond.

Containing no binder material, the single-phase polycrystalline diamond is harder than single-crystal diamonds and overcomes their drawback, i.e., cleavage.

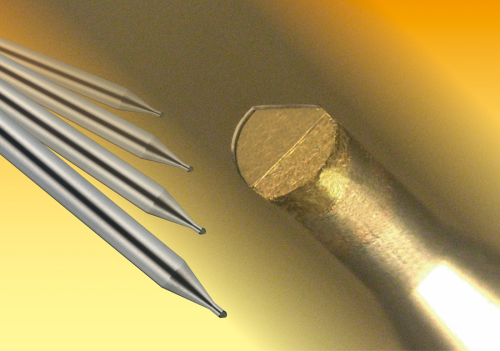

To broaden the innovative diamond's application to cutting tools, Sumitomo Electric has developed ball end mills and turning bites tipped with Sumidia Binderless, for cemented carbide and other hard brittle materials, while Sumitomo's A.L.M.T. Corp. has developed cutting tools for ultra-high precision machining of hard brittle materials, such as in making the moulds used to produce optical components.