Imagine smart materials that can morph from being stiff as wood to as soft as a sponge – and also change shape.

Engineers at Rutgers University-New Brunswick have now used four-dimensional (4D) printing to produce such materials, which could find use in a range of applications, including better shock absorption, morphing airplane or drone wings, soft robotics and tiny implantable biomedical devices. They report their research in a paper in Materials Horizons.

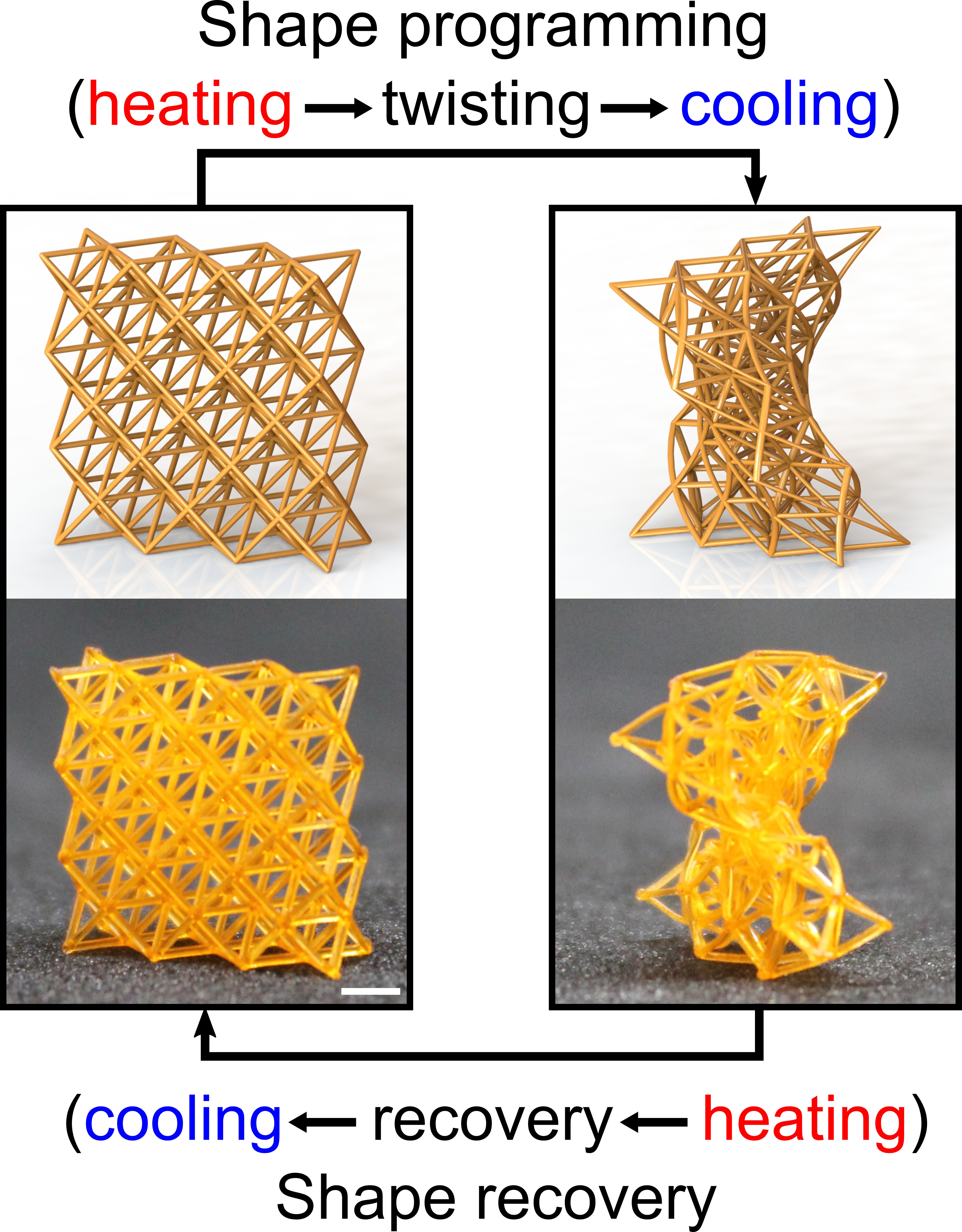

Three-dimensional (3D) printing, also known as additive manufacturing, turns digital blueprints into physical objects by building them up layer-by-layer. According to senior author Howon Lee, an assistant professor in the Department of Mechanical and Aerospace Engineering, 4D printing is based on this technology, with one big difference: it uses special materials and sophisticated designs to print objects that change shape in response to environmental conditions such as temperature. Time is the fourth dimension that allows the objects to morph into a new shape.

"We believe this unprecedented interplay of materials science, mechanics and 3D printing will create a new pathway to a wide range of exciting applications that will improve technology, health, safety and quality of life," Lee said.

The engineers created a new class of ‘metamaterials’ – materials engineered to have unusual and counterintuitive properties that are not found in nature. The word ‘metamaterials’ is derived from the Greek word ‘meta’, which means ‘higher’ or ‘beyond’.

Previously, the shape and properties of metamaterials were irreversible once they were manufactured. But the Rutgers engineers can tune their plastic-like materials with heat, so they stay rigid when struck or become soft as a sponge to absorb shock.

The stiffness of these materials changes more than 100-fold between room temperature (73°F) and 194°F, allowing a great deal of control over shock absorption. The materials can be reshaped for a wide variety of purposes, allowing them to be temporarily transformed into any deformed shape and then returned to their original shape on demand when heated.

This means the materials could be used to produce airplane or drone wings that change shape to improve performance, and in lightweight structures such as solar panels that are collapsed for space launches and then reformed in space.

Soft robots made of soft, flexible and rubbery materials inspired by the octopus could have variable flexibility or stiffness that is tailored to the environment and task at hand. Tiny devices inserted or implanted in people for diagnosis or treatment could also be temporarily made soft and flexible for minimally invasive and less painful insertion into the body.

This story is adapted from material from Rutgers University, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.