NASA reports that its Perseverance rover, scheduled to land on Mars on 18 February 2021, features 11 3D printed metal parts.

According to the organization, five metal parts 3D printed by Carpenter Additive Manufacturing form part of Perseverance's Planetary Instrument for X-ray Lithochemistry (PIXL) instrument found in the rotating turret at the end of the rover's 7-foot-long (2-meter-long) robotic arm. To make the instrument as light as possible, the JPL team designed PIXL's two-piece titanium shell, a mounting frame, and two support struts that secure the shell to the end of the arm to be hollow and extremely thin, with three or four times less mass than if they'd been produced conventionally, NASA said.

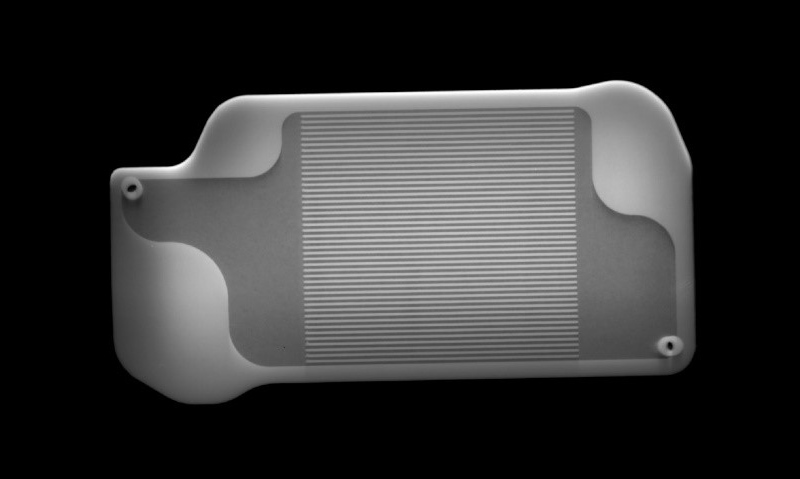

The six other 3D printed parts are heat exchangers located in the Mars Oxygen In-Situ Resource Utilization Experiment (MOXIE) aimed at testing technology to produce industrial quantities of oxygen to create rocket propellant on Mars, helping astronauts launch back to Earth.

The nickel-alloy parts are 3D-printed as a single piece, while a conventionally machined heat exchanger would need to be made out of two parts and welded together, according to Nasa. They were also treated in a hot isostatic press (HIP) ensure they were suitable for spaceflight.

This story uses material from NASA, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.