Last year, Shell International BV and GE Additive unveiled the results of a joint design and engineering project – an additively manufactured (AM) oxygen hydrogen micromixer. This complex, non-functional demonstration part was printed in nickel alloy 718 on a GE Additive Concept Laser M Line system, installed at Shell’s 3D Printing CoE and Workshop, part of the company’s Energy Transition Campus Amsterdam (ETCA) in the Netherlands.

Shell operates a 3D printing facility at ETCA next to its scientists and partner companies to use AM to prototype, as well as print functional parts. Having its own printing capability grants Shell’s R&D department the freedom and speed to create novel parts not available in the market and solve new technical challenges in support of the energy transition.

As Joost Kroon, an additive technology subject matter expert at Shell, explains: “We really wanted to put the M Line through its paces and test it to its limits. Working with the GE Additive team we agreed to apply additive technology to reimagine a large, complex part, incorporating channels that would be difficult to manufacture conventionally. Working on an oxygen hydrogen micromixer aligns well with our companies’ strategies to play a positive role in the energy transition.”

Geometry in nature

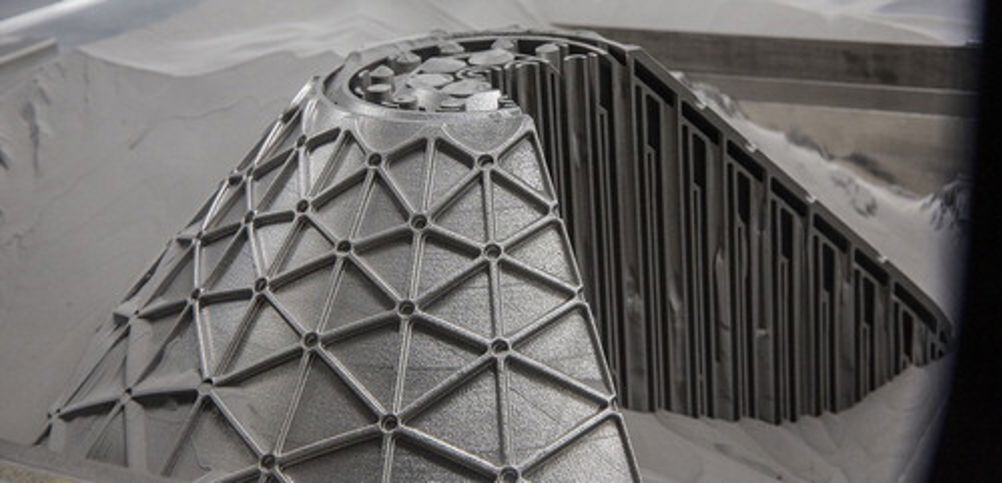

Sonali Sonawane Thakker, a lead design engineer at GE Additive’s AddWorks team based in Munich, was tasked with researching, designing and iterating the final design, which was displayed at German 3D printing event Formnext. Her mission was to design a part that was large and complex and incorporated channels for hydrogen and compressed oxygen. Sonawane Thakker was able to deploy the design freedoms that additive technology affords to rethink the structure and the shape of the part.

“Once we had settled on a part, our preliminary research showed that existing micromixers – also known as hydrogen-oxygen burners – are typically cylindrical, when conventionally manufactured, to accommodate the complex layout of tanks, pipes and nozzles,” she said. “For additional complexity we chose a large conical design and also moved from a flat to a curved structure with an ISO grid to increase the overall strength, rather than a customary flat one.”

Sonawane Thakker sought inspiration from geometries and symmetry in the natural world, in particular the Fibonacci sequence replicated in flowers and petals.

“With over 330 individual nozzles to incorporate in a circular pattern, I took inspiration from the ways pollen grains form in a flower head. The curved wall and the conical shape also reflect the shape of a petal,” she added.

Build and post-processing

Following feasibility reviews and iterations by Shell and GE Additive teams, the design and dimensions of the reimagined part were finalized, and nickel alloy 718 was chosen as the material for the build.

Dimension of the part:

Height: ~296 mm

Diameter: 484 mm

Other: X ~ 429 mm Y ~490 mm

The build preparation and printing of the part on the M Line were overseen by Lisa Kieft-Lenders, team lead, and Dennis Boon, a technician at the Shell 3D Printing Center of Excellence and Workshop.

“We have been involved in the project from the outset and have therefore been particularly close to this build and invested in its success,” said Kieft-Leenders. “Given this is one of, if not the largest and most complex part built on an M Line so far, we’ve remained in close contact with the GE Additive team in Munich and were supported on the ground here in Amsterdam by their local field service engineers. After some adaptions at the start, the build ran smoothly over nine days.”

Post processing was also completed at the Shell facility, and this was made easier through inclusion of powder removal holes, incorporated by Sonawane Thakker during the design phase.

“I cannot underestimate the power of collaboration and problem solving during this project,” said Rob Dean, GE Additive’s AddWorks leader in EMEA.