Elementum 3D, which makes technology for additive manufacturing (AM), has been issued patents in the US, Canada, and Australia for its 3D printing core technology.

According to the company, its reactive additive manufacturing (RAM) technology can expand the range of potential AM materials by enabling the printing of previously unprintable materials.

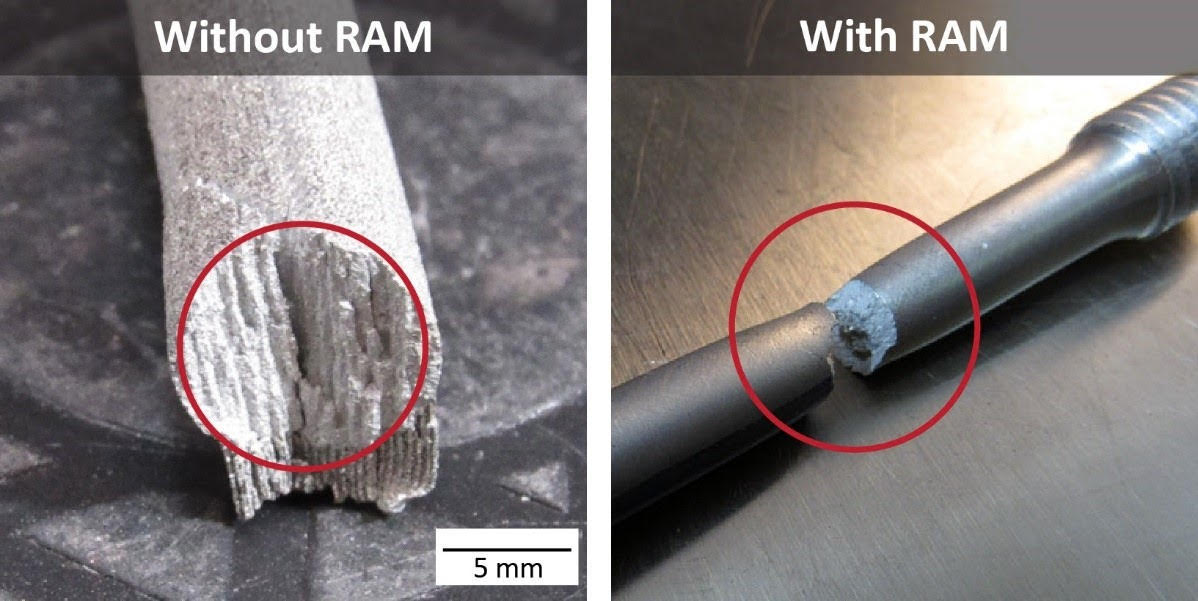

This includes high strength wrought aluminum alloys, that could not previously be printed because they suffer hot tearing (solidification cracking), resulting in parts with very poor mechanical properties, Elementum said. The RAM process forms sub-micron inoculants in the melt pool that nucleate aluminum grains to produce a fine equiaxed microstructure for better printability and improved performance.

The company can use the technology to create printable, high-performance alloy powders based on established wrought alloys, aluminum 1000, 2024, 6061, 7050, and 7075, as well as superalloys and metal ceramic composites for laser powder bed fusion (LPBF) printing.

‘Our revolutionary technology advances metals development for additive manufacturing at an unprecedented pace. It gives engineers the extra degree of freedom they have never experienced, inspiring them to bring into existence new and innovative applications,’ said Dr Jacob Nuechterlein, company present.

This story uses material from Elementum 3D, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.