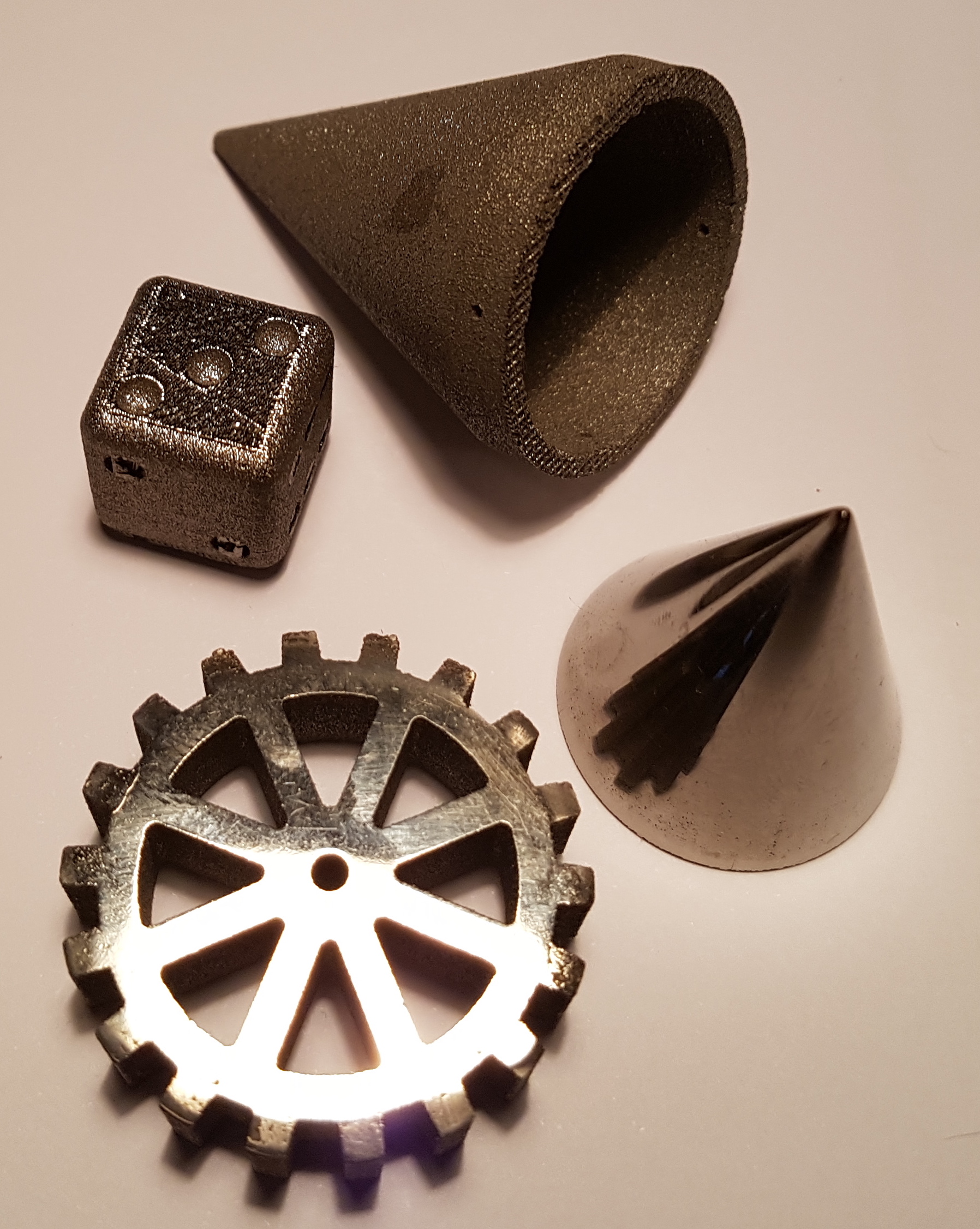

Investor AM Ventures (AMV) and Exmet AB, which works with amorphous metal alloys, have entered into an investment agreement to develop Exmet's technology for the additive manufacturing (AM) of amorphous metals. The agreement also aims to shorten the time to market for new functional products. Exmet has set up manufacturing facilities with an EOS M 290 3D printing system and opened new offices in Stockholm. Amorphous metal alloys, also known as bulk metallic glasses (BMG) and glassy alloys, lack the crystalline microstructure found in ordinary alloys, such as steels. According to Exmet, their development been hampered since the 1960s since no suitable and general manufacturing method has been available. Using Exmet AB's AM based technology the excellent properties of these glassy alloys can be better exploited as it removes the limits set by casting, melt spinning and thermoplastic forming in manufacturing of amorphous metals. The result is products of almost any alloy, such as iron, titanium, aluminum, magnesium or cobalt based, and shape, virtually unaffected by corrosion, with low magnetization loss. Exmet says that the extreme strength of the materials allows for greater weight reductions. ‘We are looking forward to support Exmet on their way to amorphous metal parts with completely new and unique properties,’ said Johann Oberhofer, executive vice president technology, AMV. ‘AMV also will assist Exmet and their customers when it comes to ramping up specific successful amorphous metal components to economic serial production to fully exploit the superior mechanical and magnetic properties of these components.’

This story uses material from Exmet, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.