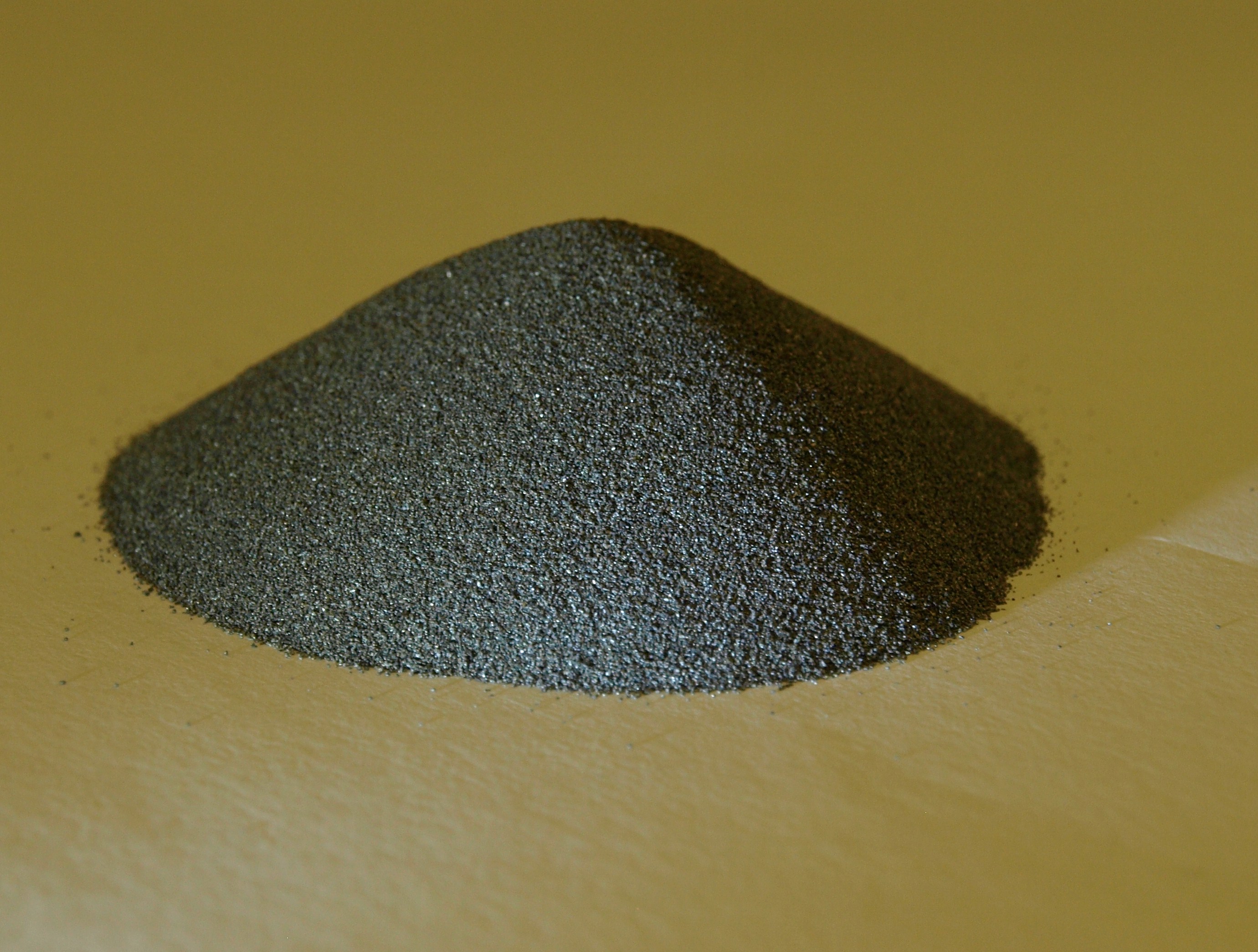

LPW and Metalysis have formed a collaboration to develop clean, spherical tantalum and tungsten powders for additive manufacturing (AM).

The partnership will make use of Metalysis’s metal production technology and LPW’s spherodisation and post-processing capability. LPW will be responsible for selling the optimised powder to the AM market.

Metalysis technology, which produces metal powder directly from oxide using electrolysis, could significantly increase production volumes. Its plant in South Yorkshire, UK, is the first new primary tantalum metal production plant in Europe for more than 30 years. The patented process for producing metals, including refractory materials such as tantalum and tungsten alloys, offers both economic and environmental benefits over traditional metal production methods.

‘Metalysis offers a greener and more cost-effective process, add our specialist industry knowledge and we can then supply a range of high quality, specially developed powders for the additive manufacturing industry,’ said LPW MD, Dr Phil Carroll.

This story is reprinted from material from LPW, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.