Japanese ceramics specialist Kyocera plans to introduces a range of cutting tools at this year´s AMB metalworking trade fair in Stuttgart, Germany.

The new products include the 4JER solid endmill, an update for the face-milling cutter MFWN, the CA3 Series with a new CVD coated carbide grade and chipbreakers for cast iron machining. The 4JER solid endmill is resistant to breakage and capable of stable slotting and trochoidal machining. Kyocera´s original Megacoat hard coating technology helps ensure long tool life and stable machining. With improved chatter resistance and variable helix design, the 4JER solid endmill prevents chattering due to its unique four-flute design.

Kyocera has updated its face-milling cutter MFWN, a 90° low cutting force cutter for reduced chattering with a maximum A. R. of 13°, including neutral inserts for shouldering and facing. The line-up expansion enables efficient aluminium machining due to changed geometry and the new grade PDL025, the company says. The fine-grain cemented carbide tool grade with DLC coating improves machining quality and gives a longer tool life. The new grade is also suitable for turning and cut-off applications.

In addition to the MFWN expansion, Kyocera will show a preview of a new development for aluminium milling, the MFAH. It offers a new insert geometry with two cutting edges and features an adjustable insert seat pocket. The MFAH is available in two versions, the PCD insert grade KPD001 and the new PDL025 grade.

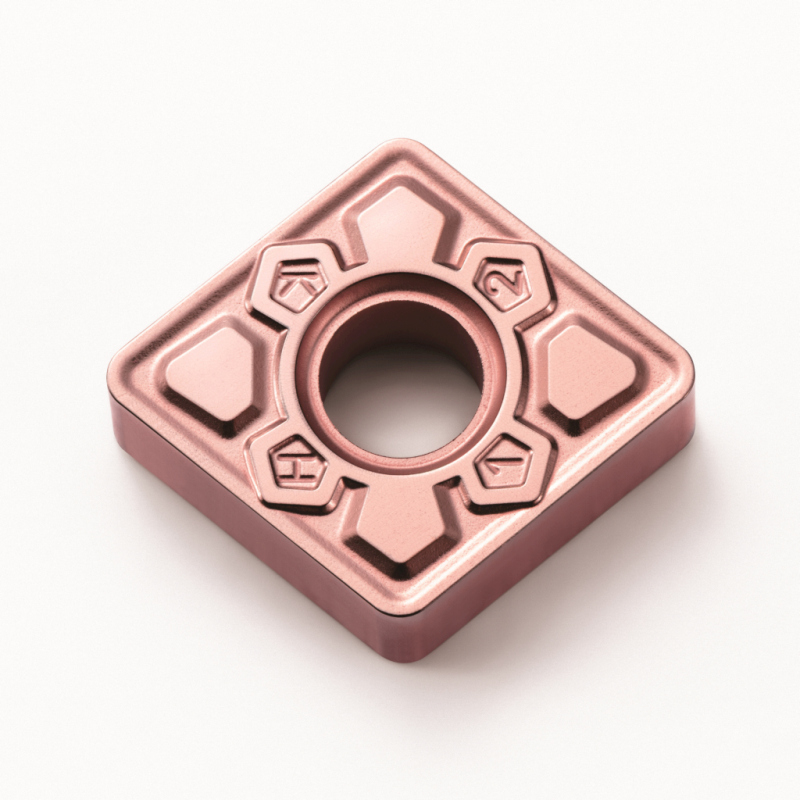

Efficient machining Kyocera's high feed cutter series combines several geometries, grades and a toolholder with line-up ranges from 16 mm to 160 mm, which enable a variety of applications. The small diameter high feed cutter MFH Micro starts from 8 mm. The low cutting force design helps ensure high efficiency machining and stable high feed machining in a wide range of cutting parameters. The features, such as a maximum ap = 0.5 mm, offer a cost down solution compared to the application of solid tools. Kyocera’s CA3 series now features a new CVD coated carbide grade and chipbreakers for cast iron machining. The coating film structure reportedly improves shock resistance while the miniaturized composition of the coating layer allows for better wear resistance. The coating interface state can prevent pealing and realizes stable machining in the cast scale. The CA3 series comes in three grade types, which are applicable for various cutting conditions. The new chipbreaker line-up is specialized for cast iron focusing on fracture resistance for wide applications in heavy cutting. Customers can select from the three chipbreaker types of sharpness, continuous and heavy interruption, according to their individual needs.

This story is reprinted from material from Kyocera, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.