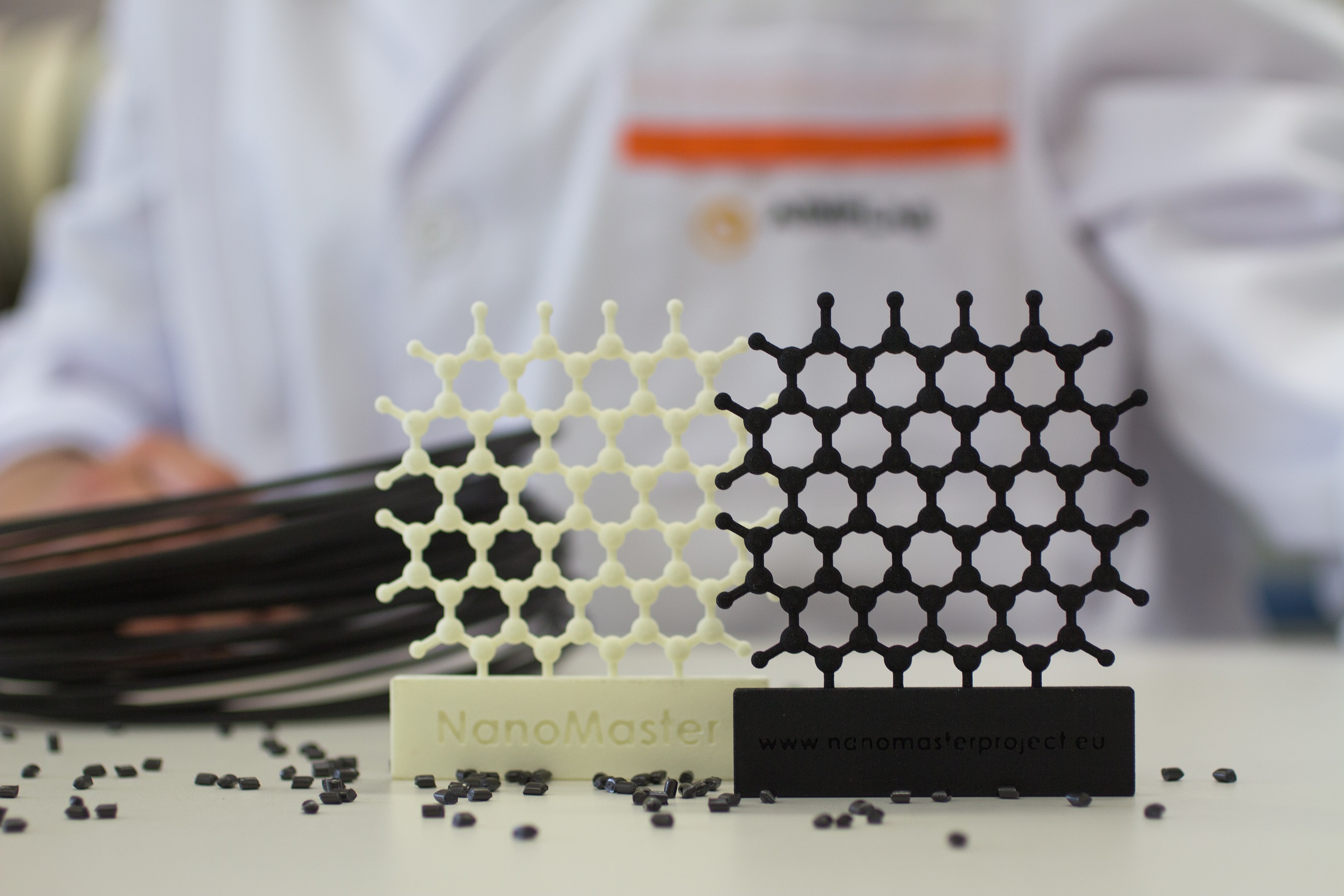

European plastics organization AIMPLAS as part of the NANOMASTER project has developed improved graphene particle masterbatches, or concentrates, suitable for use in conventional plastics processing and additive manufacturing (AM).

The particles can be used in injection and extrusion conventional processes and AM (powders for SLS and rods for 3D printing) to produce parts for cars, toys and electronic devices.

The research has concluded that the most important factors when synthesizing graphene are the number of layers, the diameter and the oxygen amount present in the particle. Graphene powder is obtained from exfoliating graphite. The greater the reduction in the number of layers, the more effective it could be, although the researchers could not consider as graphene a particle with more than one carbon atoms layer. Therefore, particle synthesis is important in order to achieve interesting properties in the plastic compounds developed.

The right graphene and nanographite processing is also essential, and of AIMPLAS’ tasks in this process has been to develop graphene nanocompounds and masterbatches to be used in injection, extrusion and AM processes. For this purpose, the processing conditions have been improved in each one of the manufacturing stages. AIMPLAS has also developed rods for 3D printing and powder for laser sintering.

This story is reprinted from material from AIMPLAS, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.