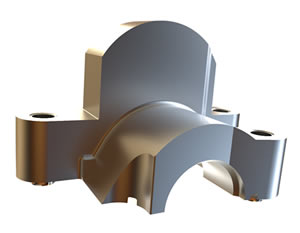

GKN Sinter Metals received the award in the automotive engine category, for the rear camshaft cap component used on Chrysler four-cylinder engines. The award recognises the inventive design and capabilities of GKN with regards to integrated functionality, unique geometry shapes, and material development. Due to its unique design shape, this part has been dubbed the "tombstone cam cap" and in the past was limited to only being produced by a die-cast process. GKN helped Chrysler redesign it for powder metal using a high-strength aluminium material, while providing improved functionality with pressed-in oil grooves. By using the full range of benefits from the powder metal process of near net shape, reduced material waste, and streamline manufacturing complexity, GKN is able to supply Chrysler with all cam caps on the Dodge Dart engine.

"We are excited to be a recipient this year of an excellence award from MPIF," said Chris Franks, president of GKN Sinter Metals Americas. "This recognition by our industry reconfirms that GKN is providing valued solutions to our customers, and continues to be on the leading edge of powder metal technology." The 2013 PM Excellence Awards recognise PM designs, emphasising the improved net shape, precision, innovative fabrication methods, production efficiency, sustainability contributions, and manufacturing cost reduction capable with powder metal technology. Visit MPIF's website for a list of all the 2013 PM Excellence Award winners.

Find us on Google? Click here to sign up to receive our weekly e-newsletter and get news sent directly to your inbox!