GE Additive says that Sandvik Additive Manufacturing has become a strategic partner in its binder jet project.

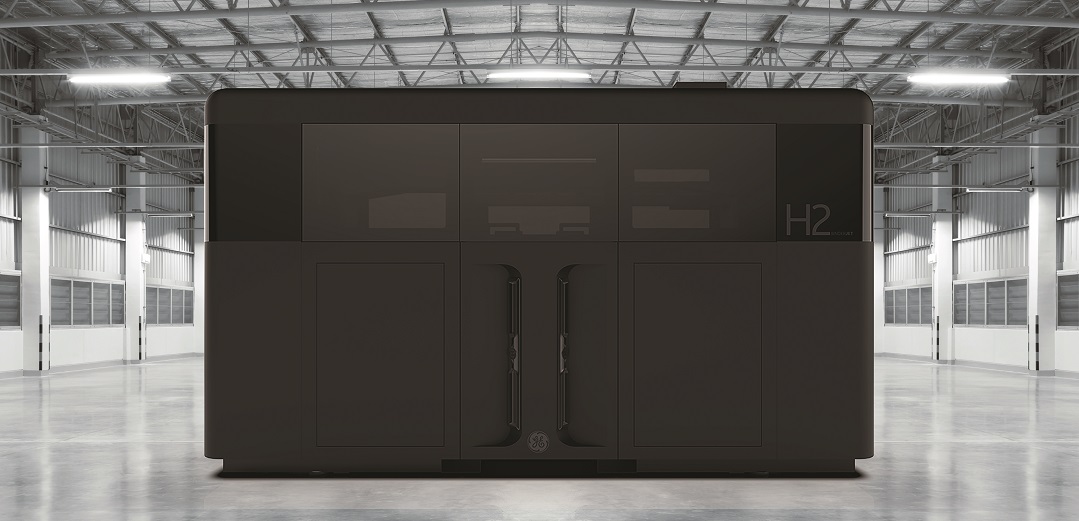

According to the company, Sandvik has become a certified powder supplier for its range of Osprey alloys to accompany GE Additive and AP&C’s own materials, and will also use GE Additive’s H2 Binder Jet beta machine.

The partner program aims at industrializing additive manufacturing (AM) technology by developing a beta system into a pilot facility, and eventually into a commercially available factory solution in 2021.

‘Our approach to binder jet is making additive mass production a reality in every industry,’ said Jacob Brunsberg, Binder Jet product line leader, GE Additive. ‘And while it would be relatively easier to launch individual machines, we continue to hear from customers, especially in the automotive industry, that they need a complete solution that can scale.’

This story uses material from GE Additive, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.